The SEPTEMBER meeting was a "Show and Tell" session at the Design and Technology Centre at St. Andrew's College, where we have been offered a "home base" for our meetings, courtesy of the College and the Centre's Director, Mr Keith van Winkel.The photos below, by Andy Hatting, John Keulder and some supplied by Graham Shepherd, give some idea of the projects described by the enthusiastic presenters.

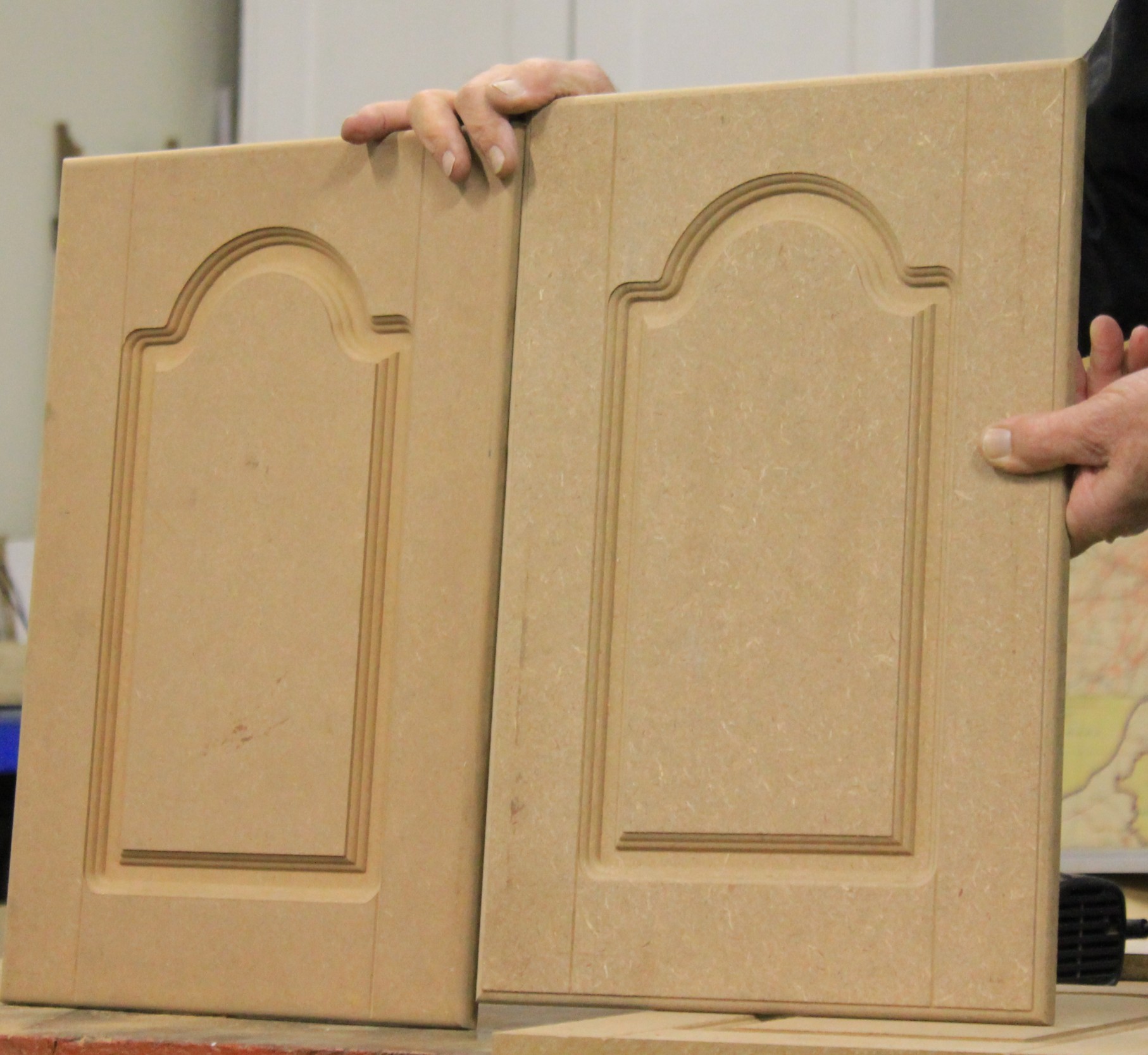

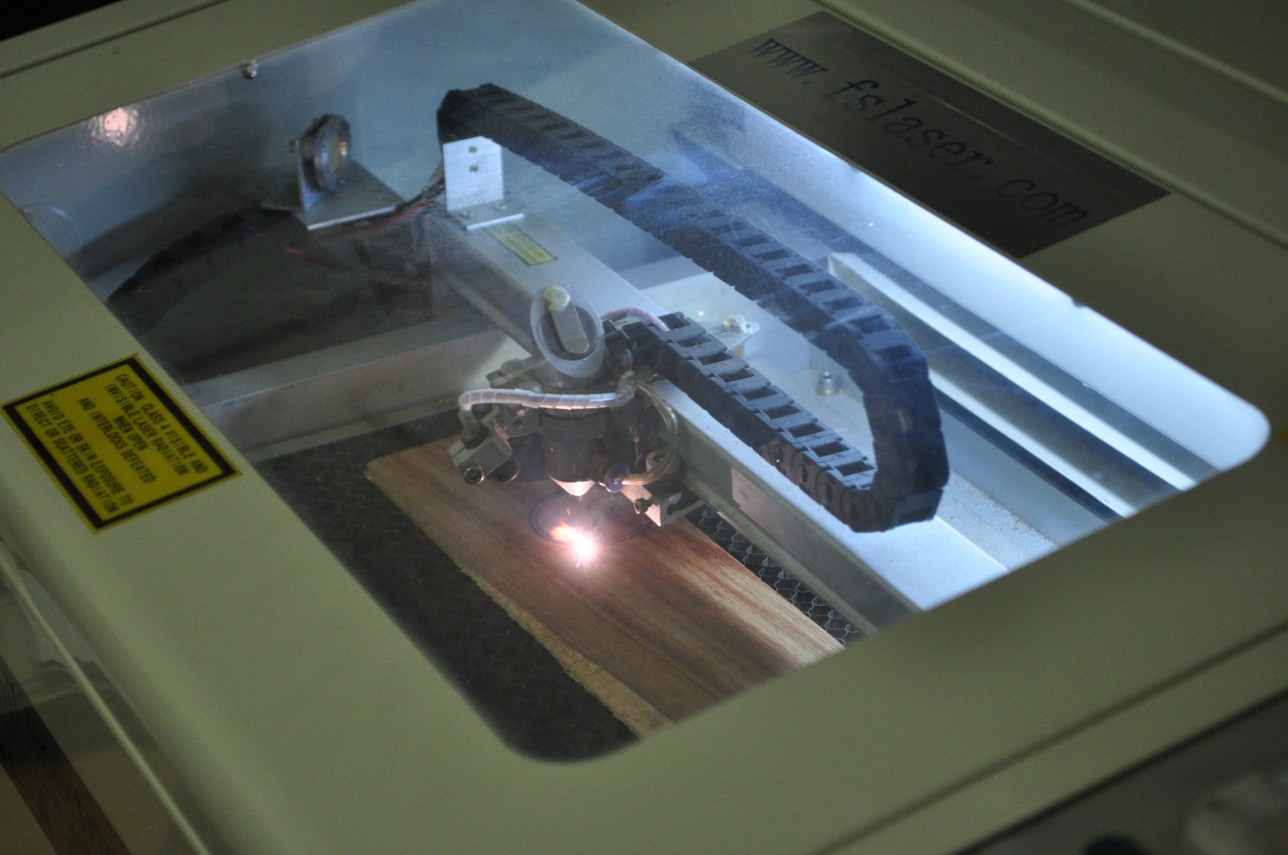

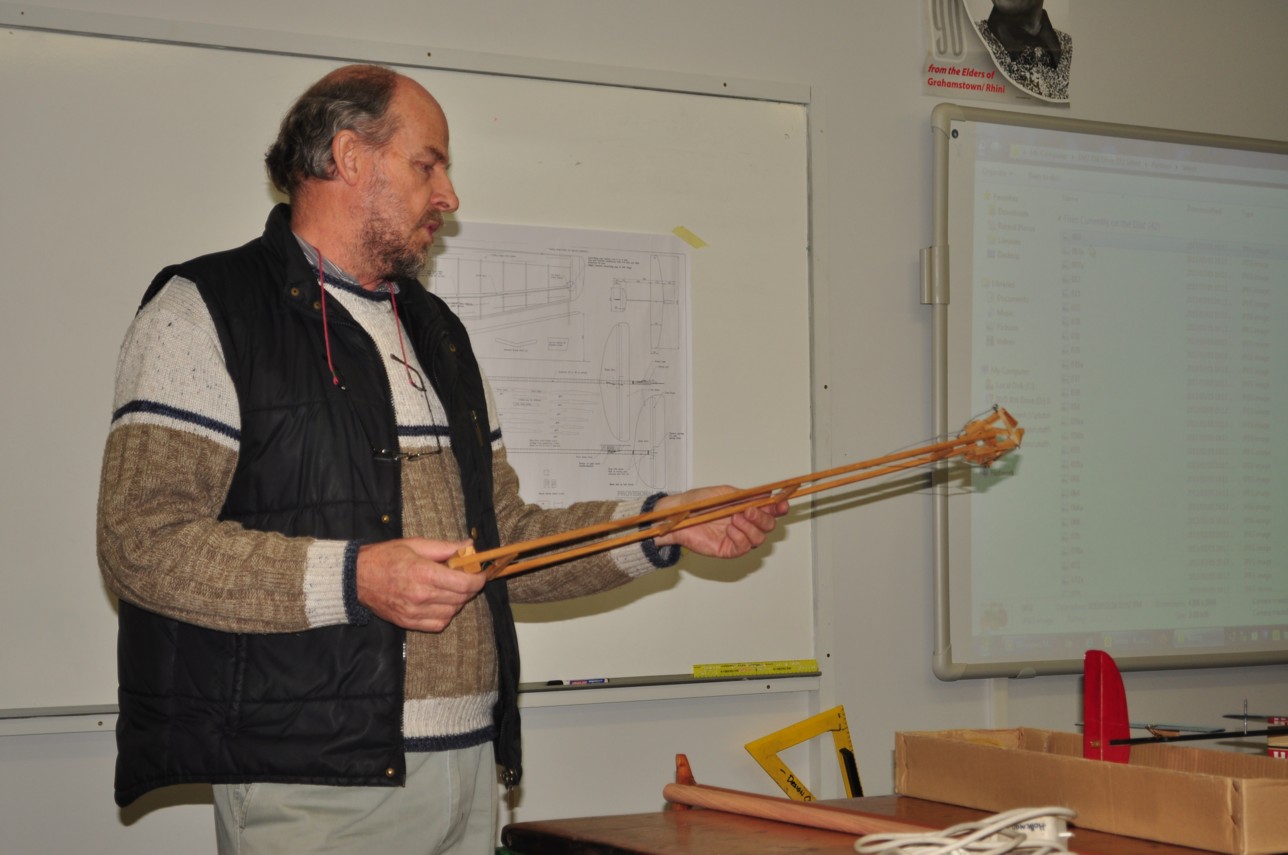

The first presentation was by Keith van Winkel, who spoke about the Centre and described some of the projects that had been done.

Entrance to the Design & Technology Centre |

Interior of the Centre |

Keith van Winkel, Director of the Centre |

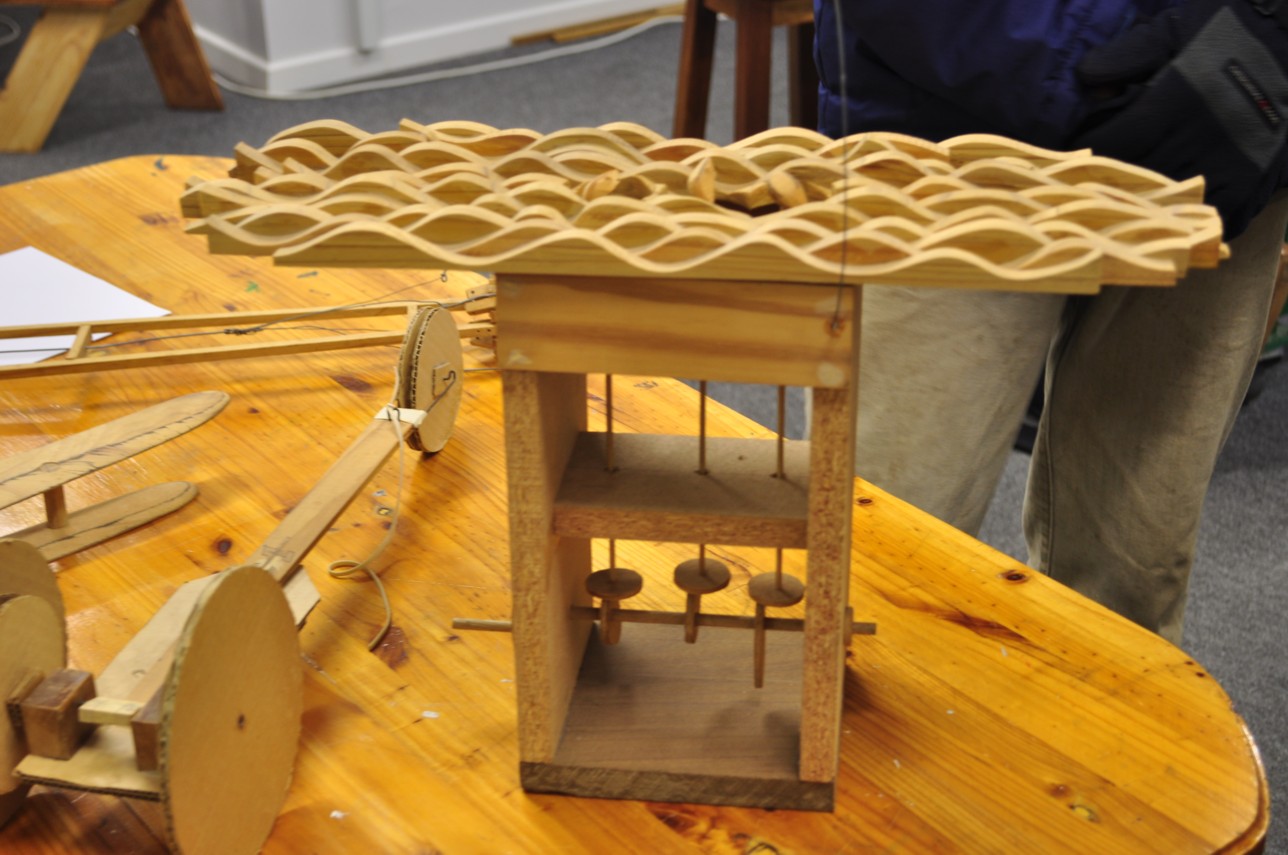

Some of the projects |

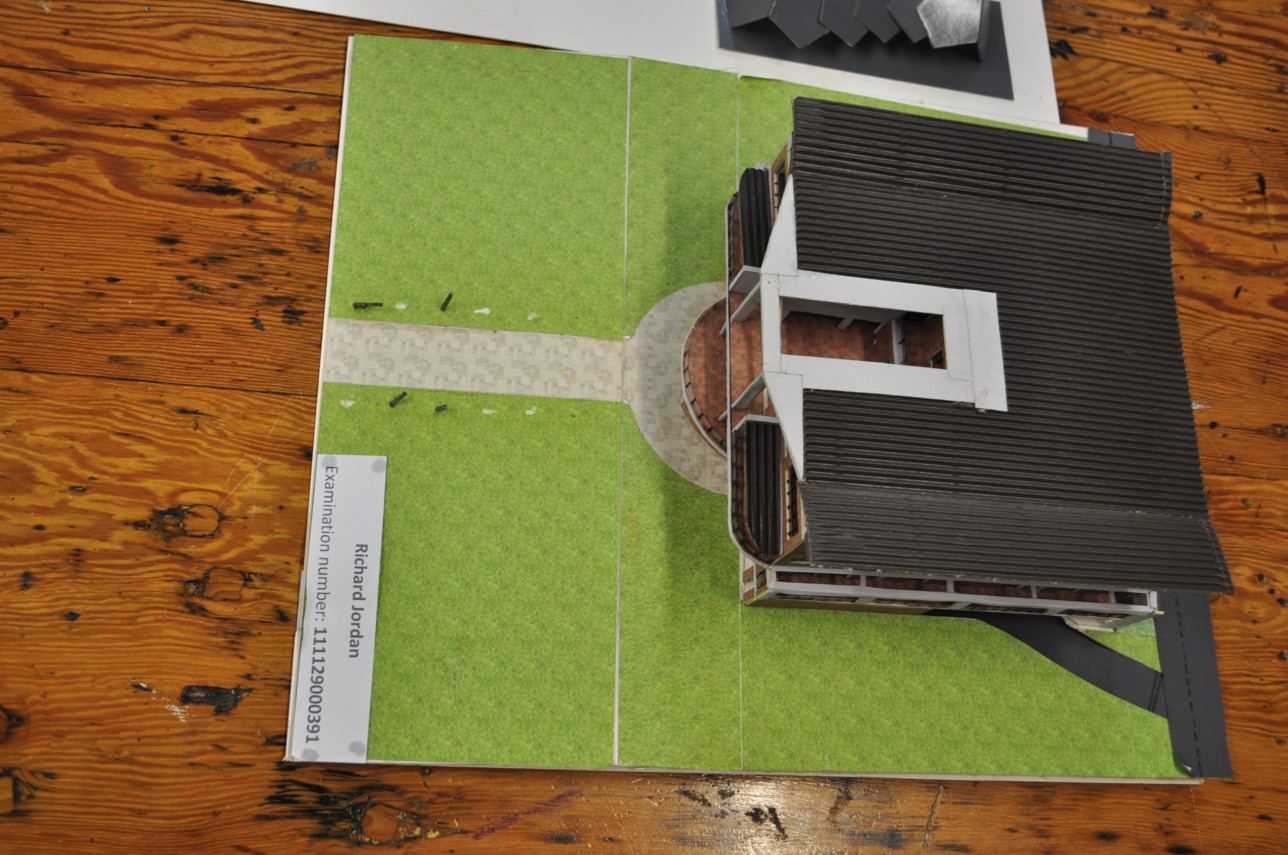

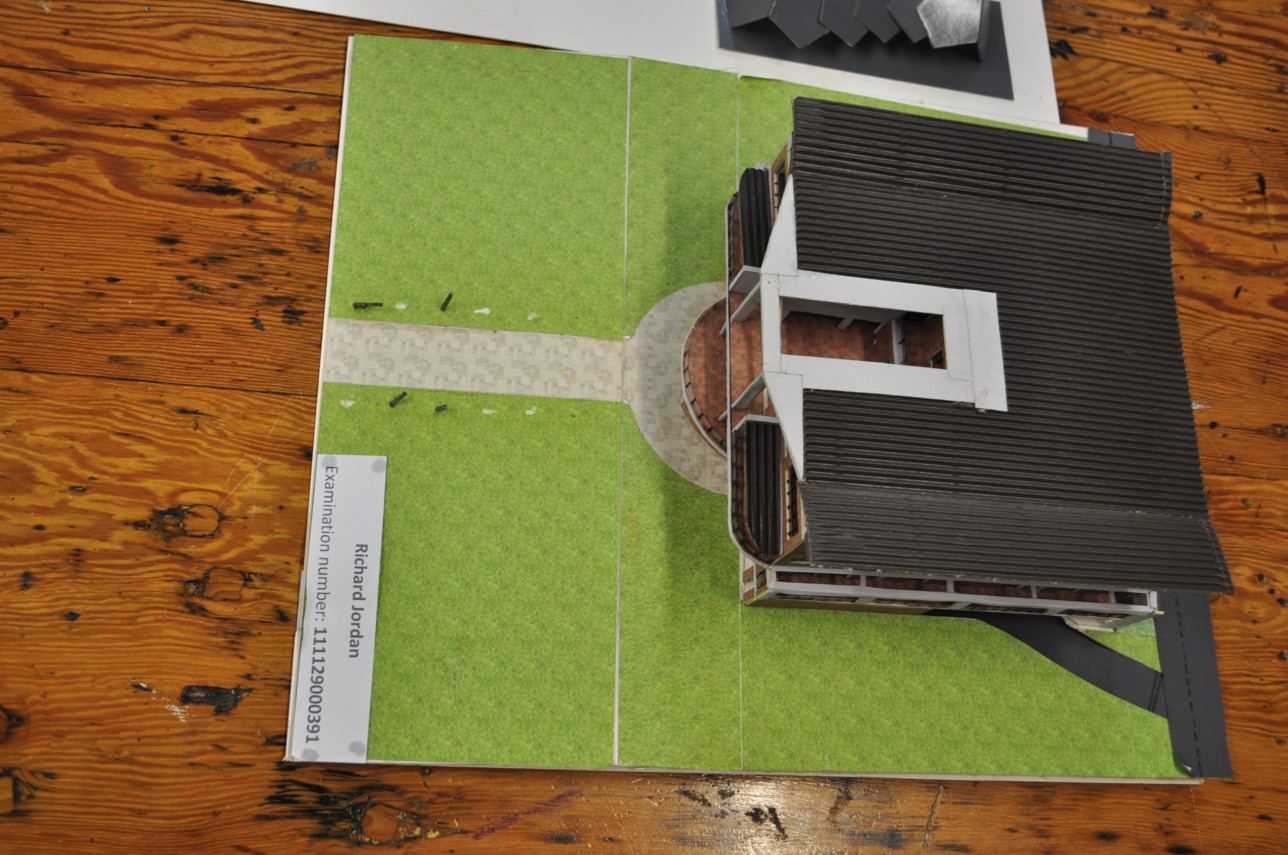

Architectural design |

More architecture |

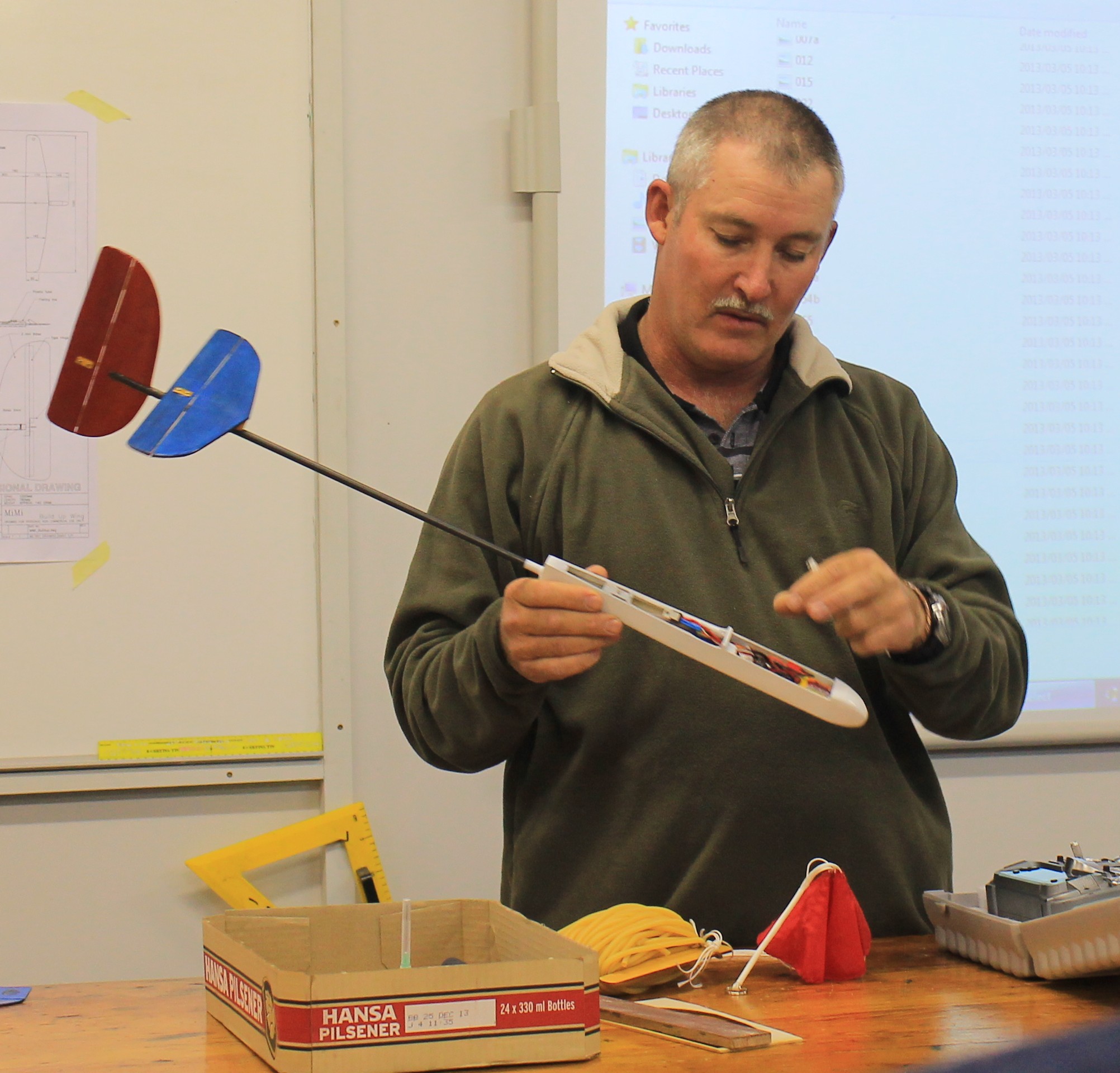

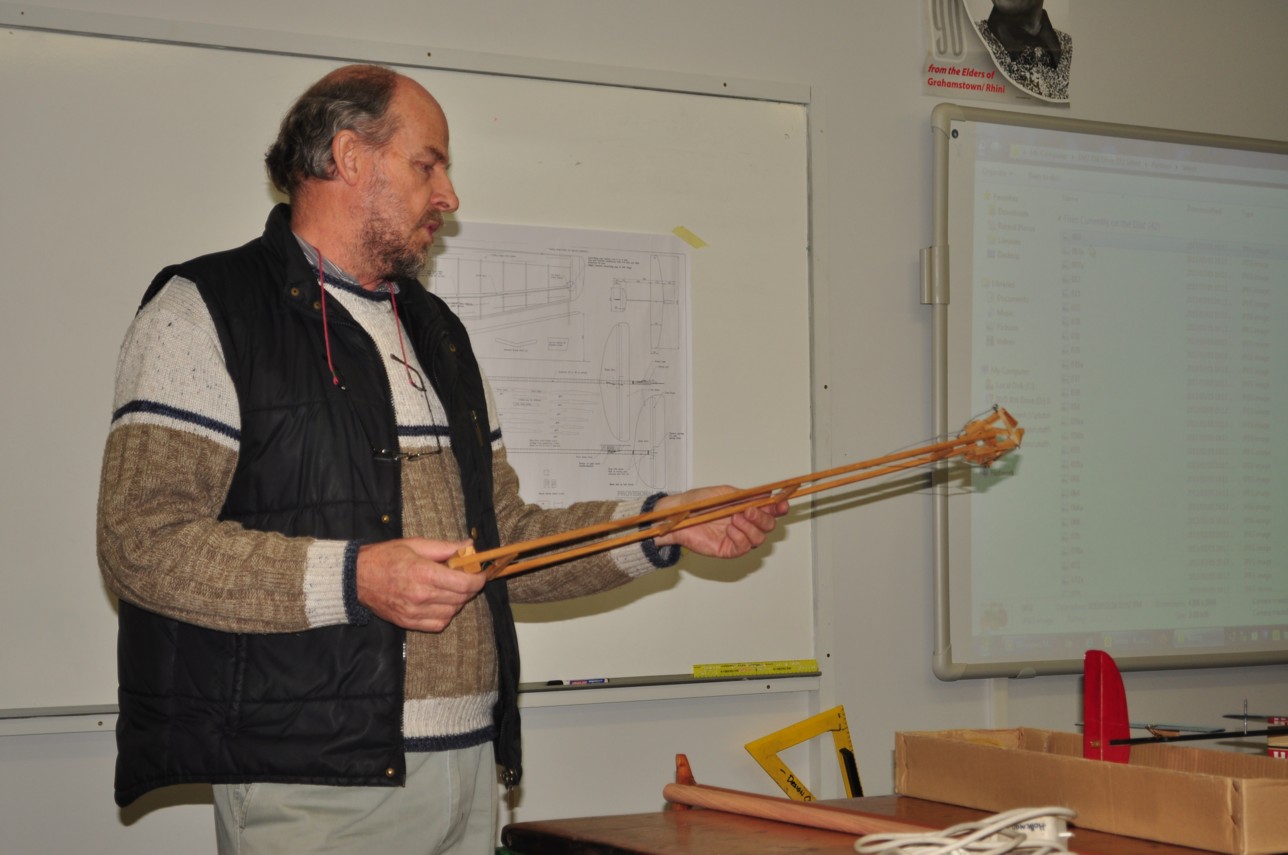

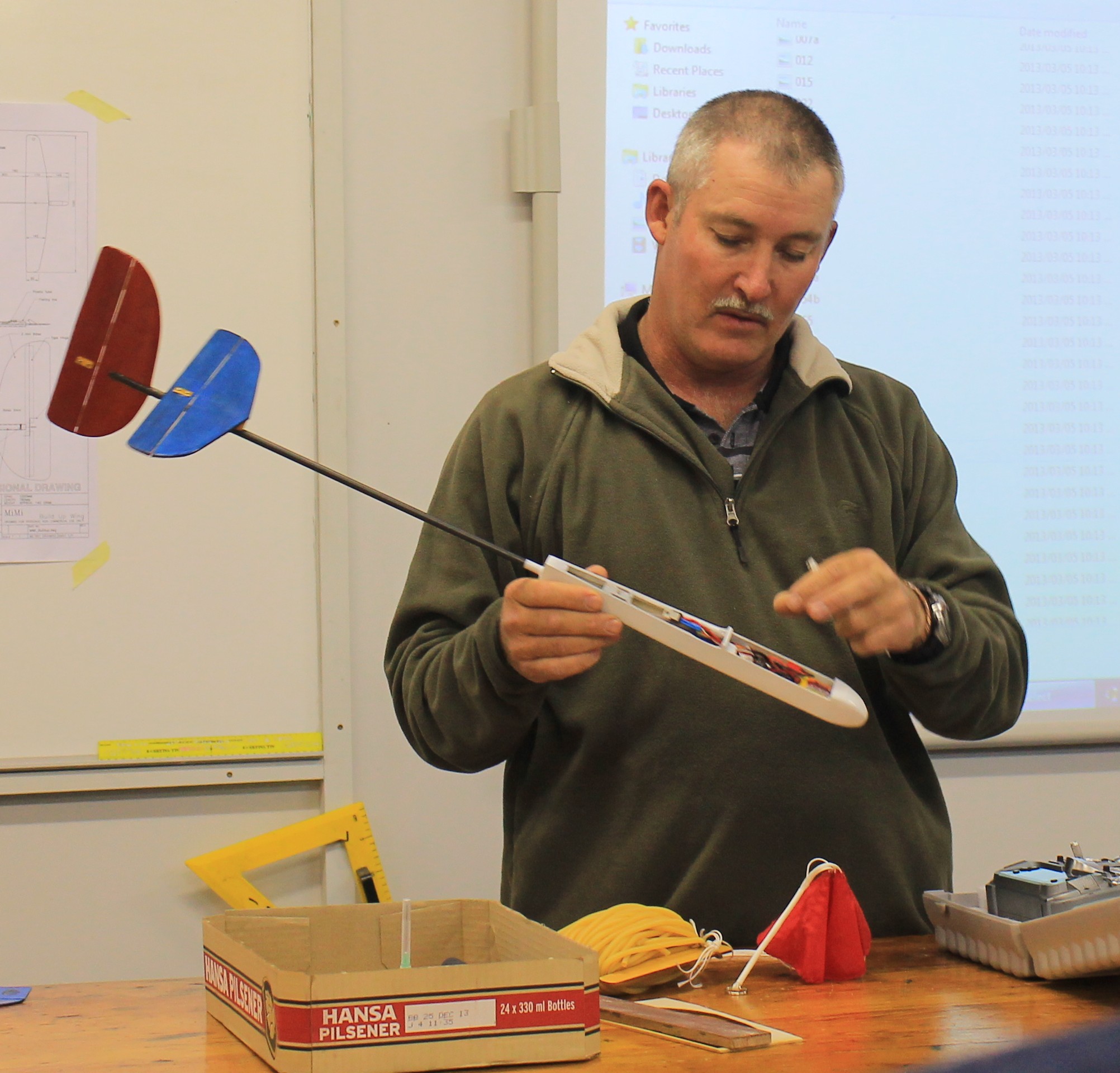

Rob Moss then spoke about turning walking sticks and making the handles and Steve Craigie demonstrated some techniques in making radio-controlled model aircraft.

Rob Moss |

Walking sticks |

The important handles |

Steve Craigie |

Model aircraft parts |

Radio control |

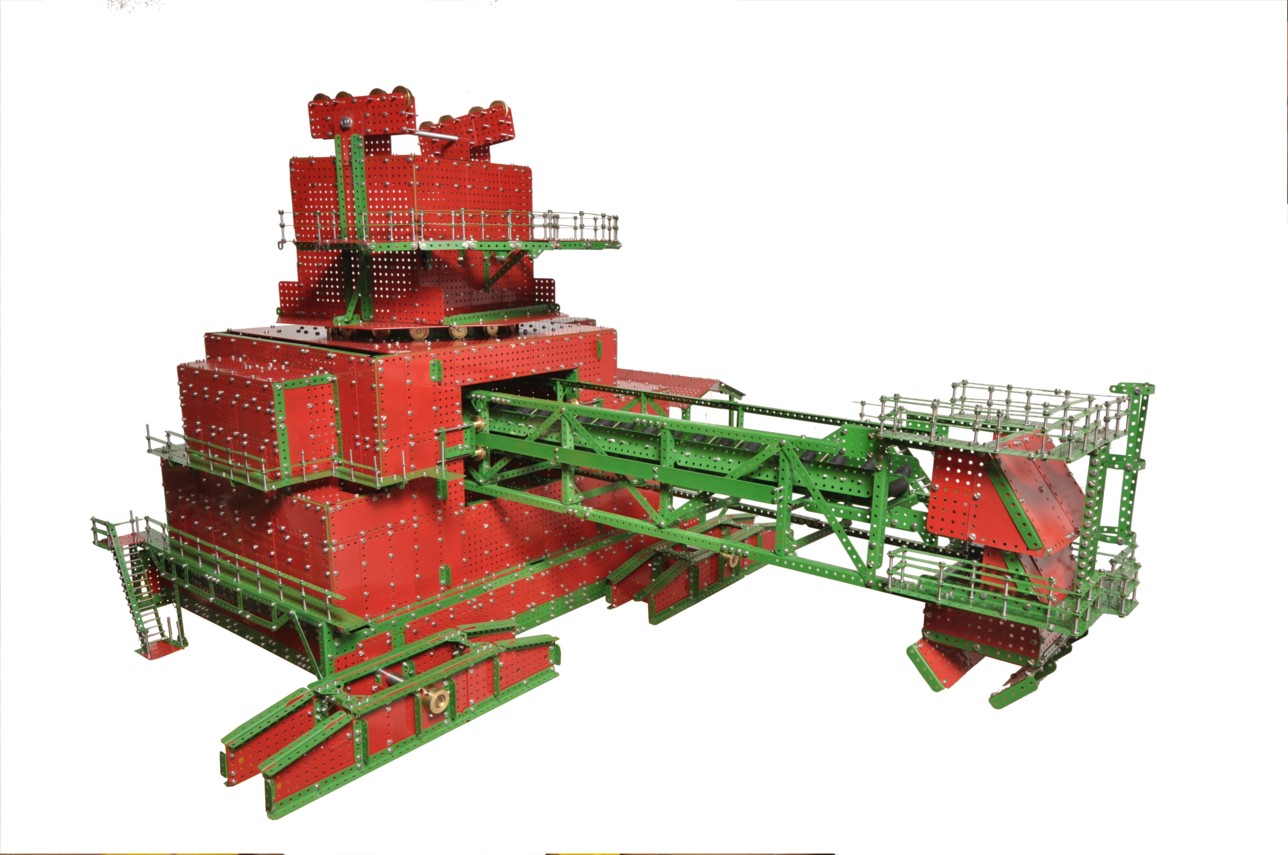

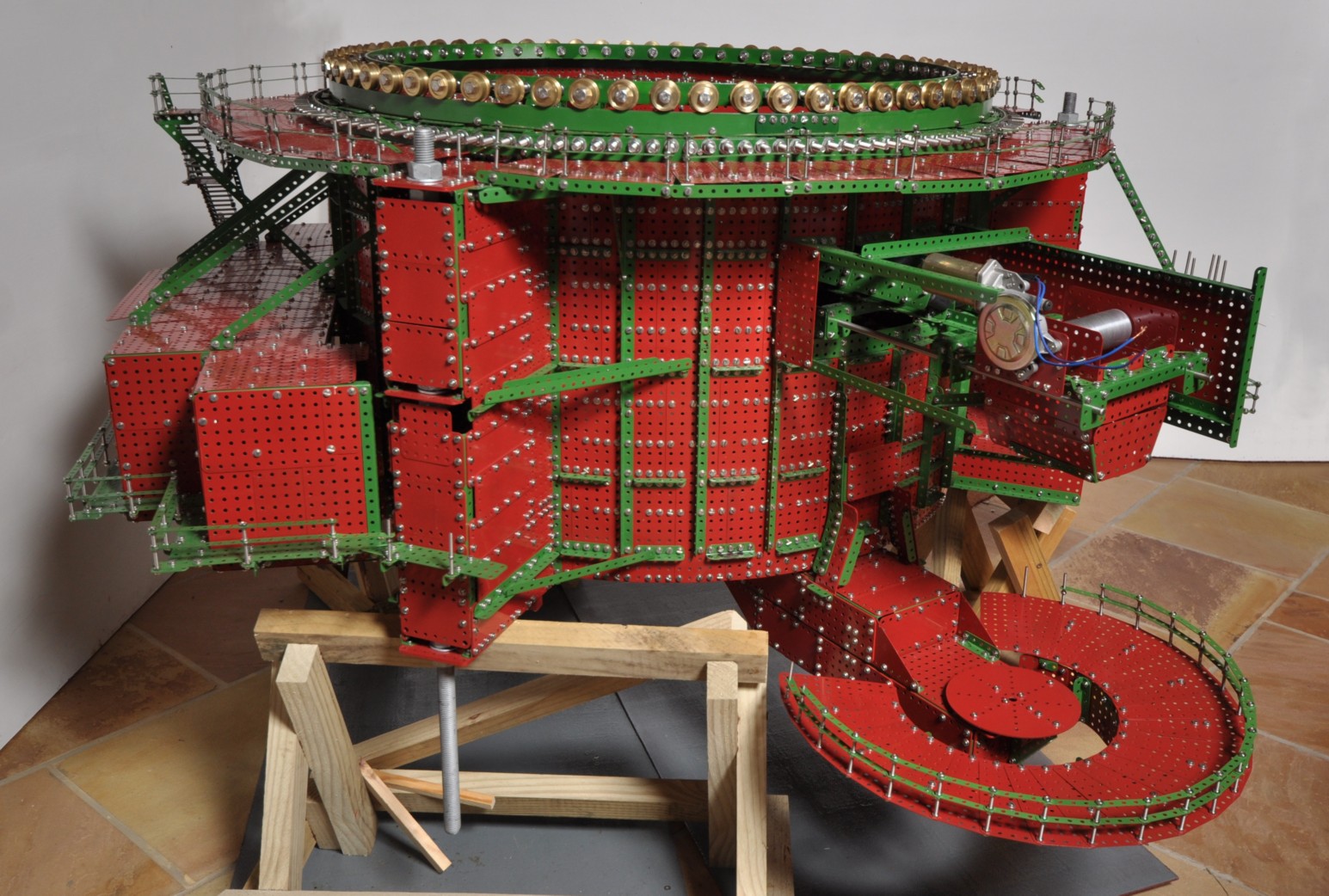

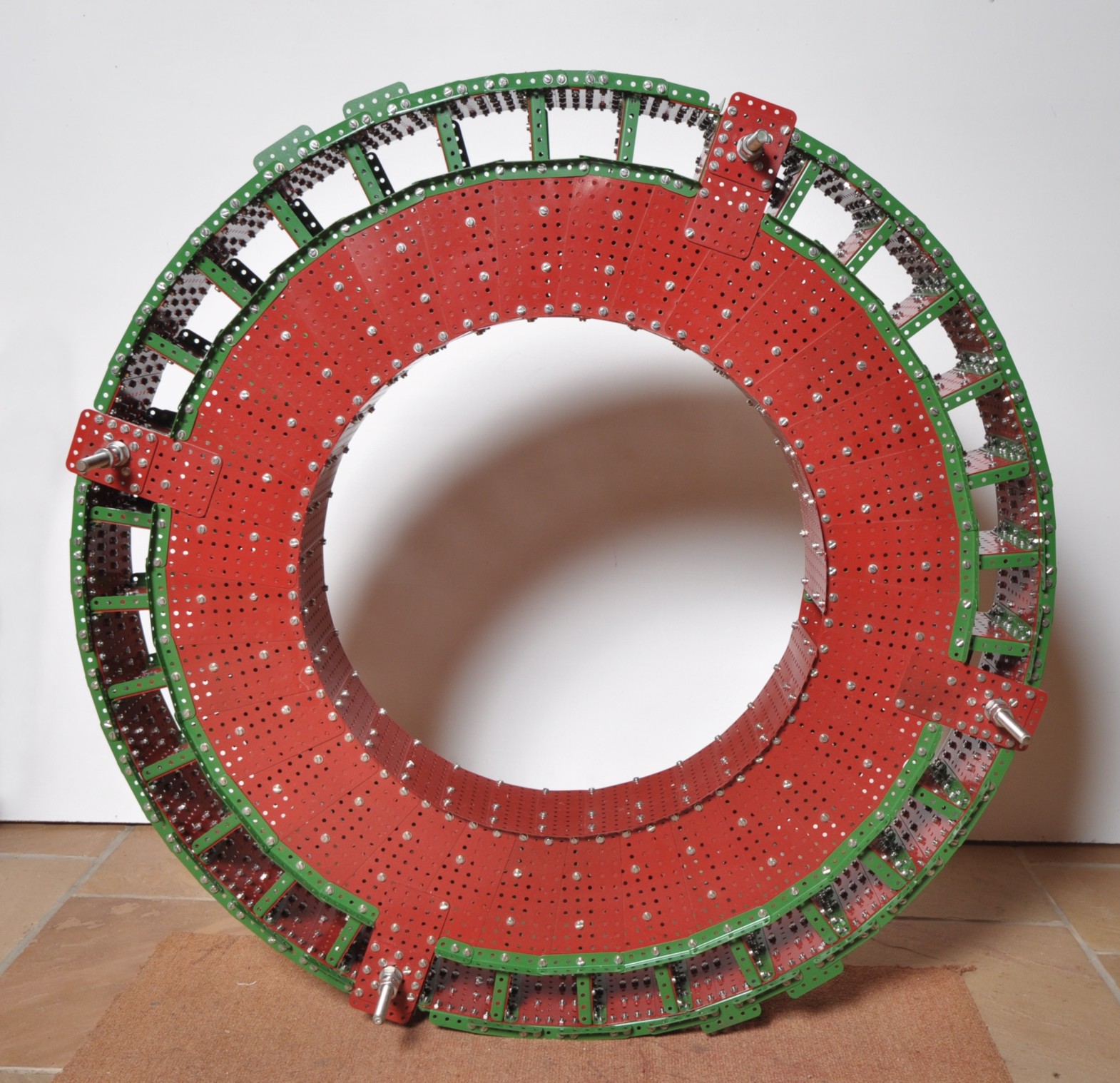

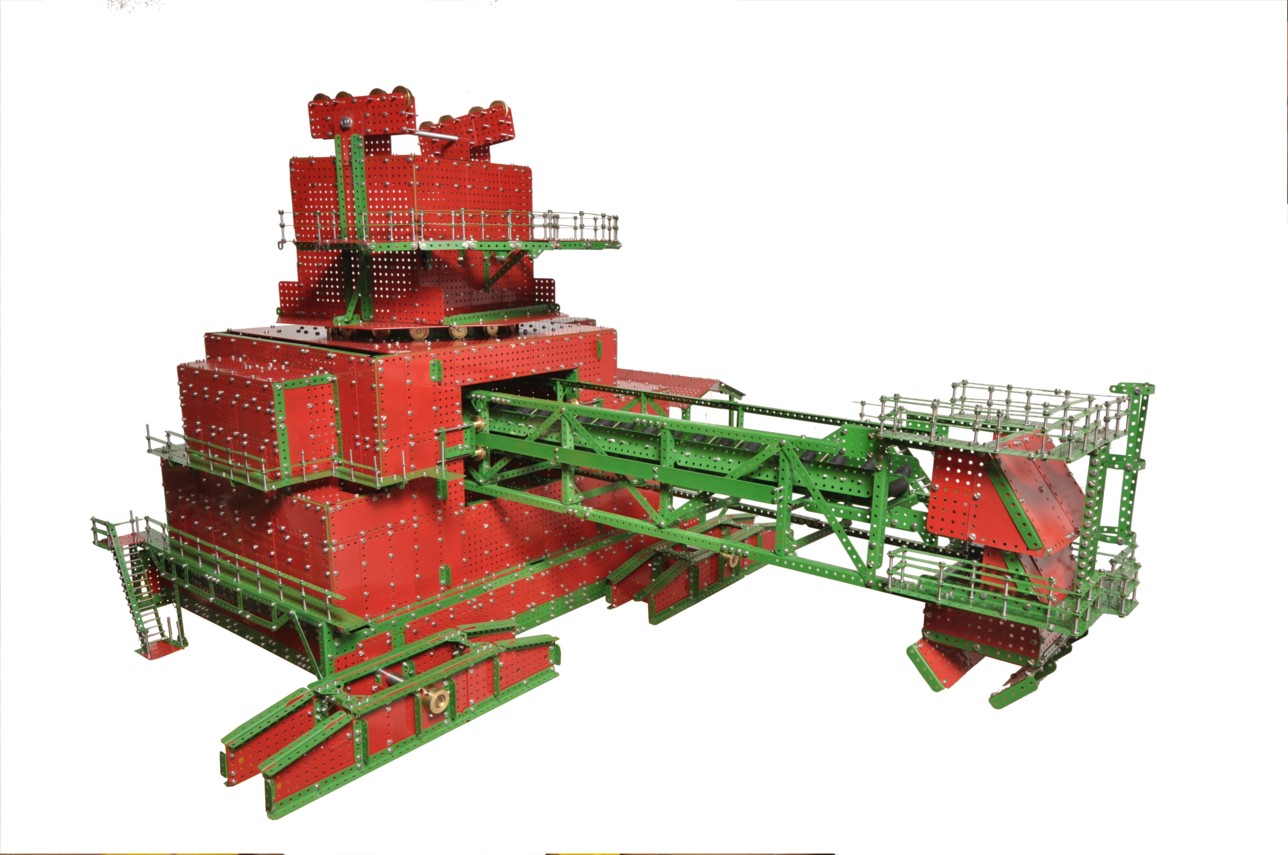

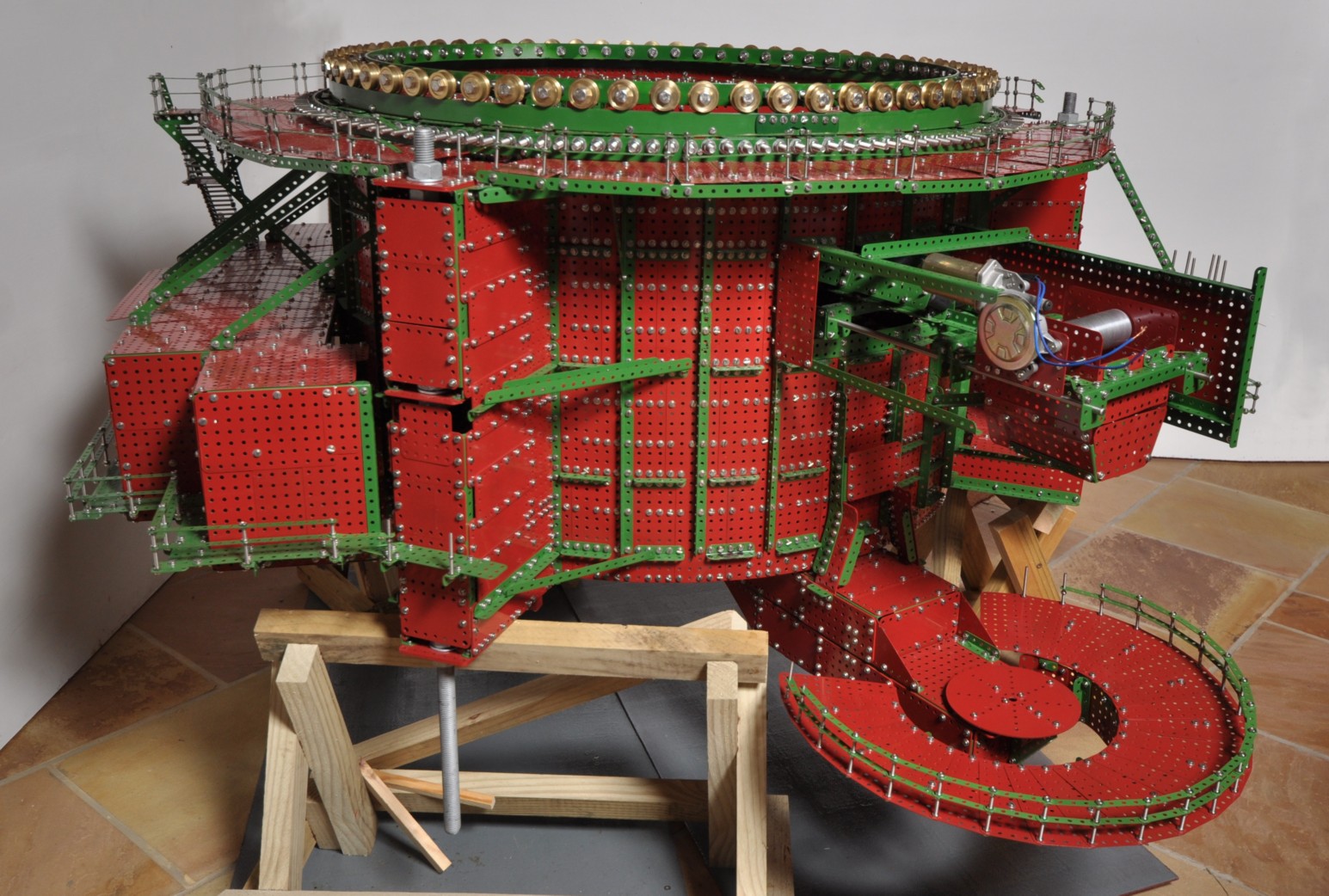

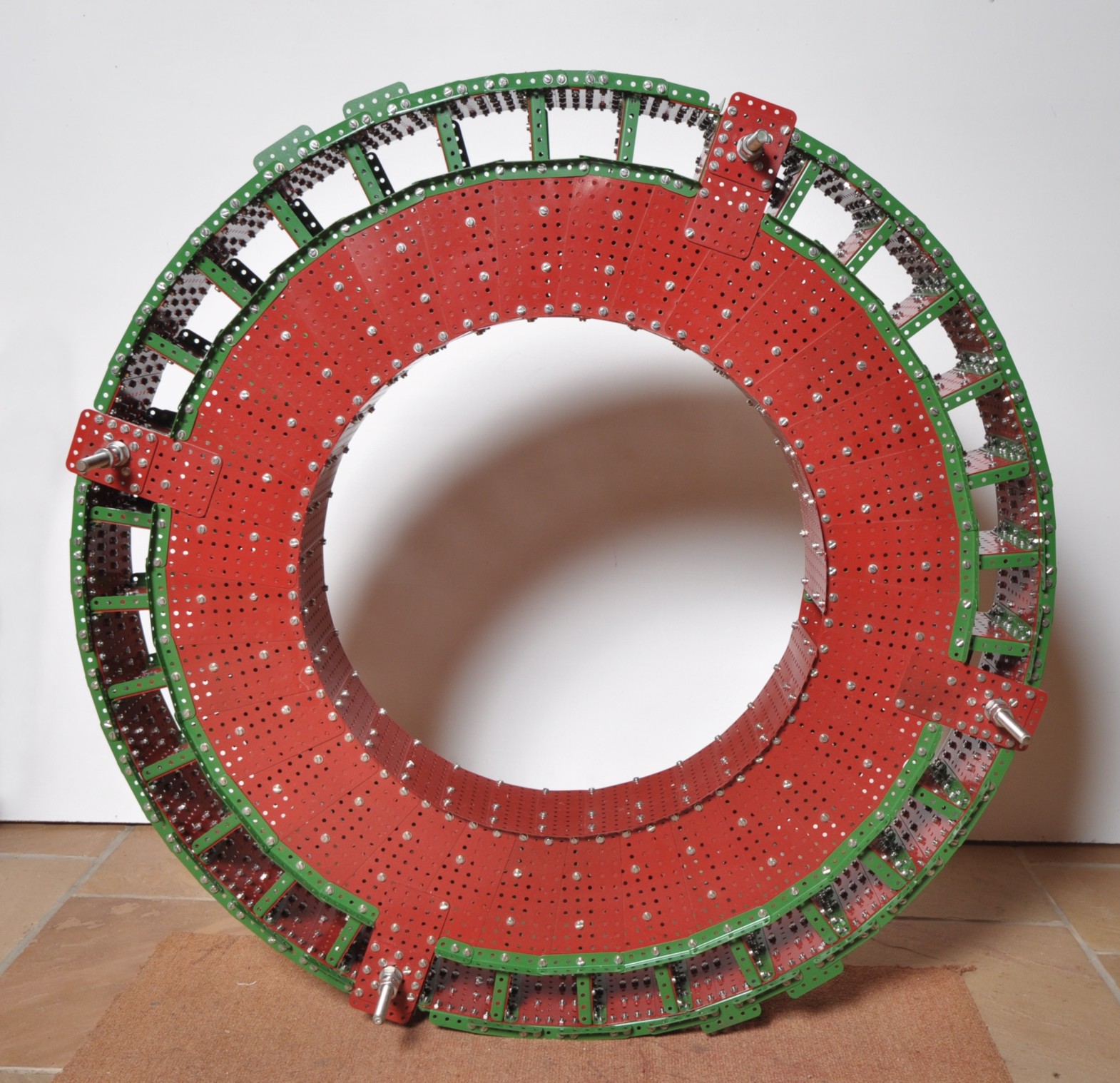

Although it had no connection with woodwork, a highlight of the evening was a talk by Grahamstown's "Mr Meccano", Graham Shepherd, who since his retirement from the Mathematics Department at Rhodes University has been building probably the largest fully working Meccano model in the world. The model is of a Bagger 288 bucket-wheel excavator made by Krupp in Germany and used for excavating and transporting 240 000 cubic metres of coal per day from the open-cast colliery to the power station.

Graham started making the parts in mid 2009 and assembly started in April 2011. In making most of the parts himself he has drilled about a million holes in 1 mm plate, which is equivalent to drilling 1 km through steel! He has used about 80 000 each of bolts, nuts and washers.

..........The actual Bagger288 .................. The MODEL

Length:.......705 feet .............................. 41 feet + 16 feet ground conveyor

Height:.......311 feet .............................. 16 feet

Mass:........14 500 tons ........................... 1250 kg

Cost:.......$100 million .......................... ?

To find out more about this amazing project, you can e-mail Graham at shepherd.meccano@gmail.com

Graham Shepherd and parts of his model |

The real thing! |

Another view |

Back to the model |

|

|

|

|

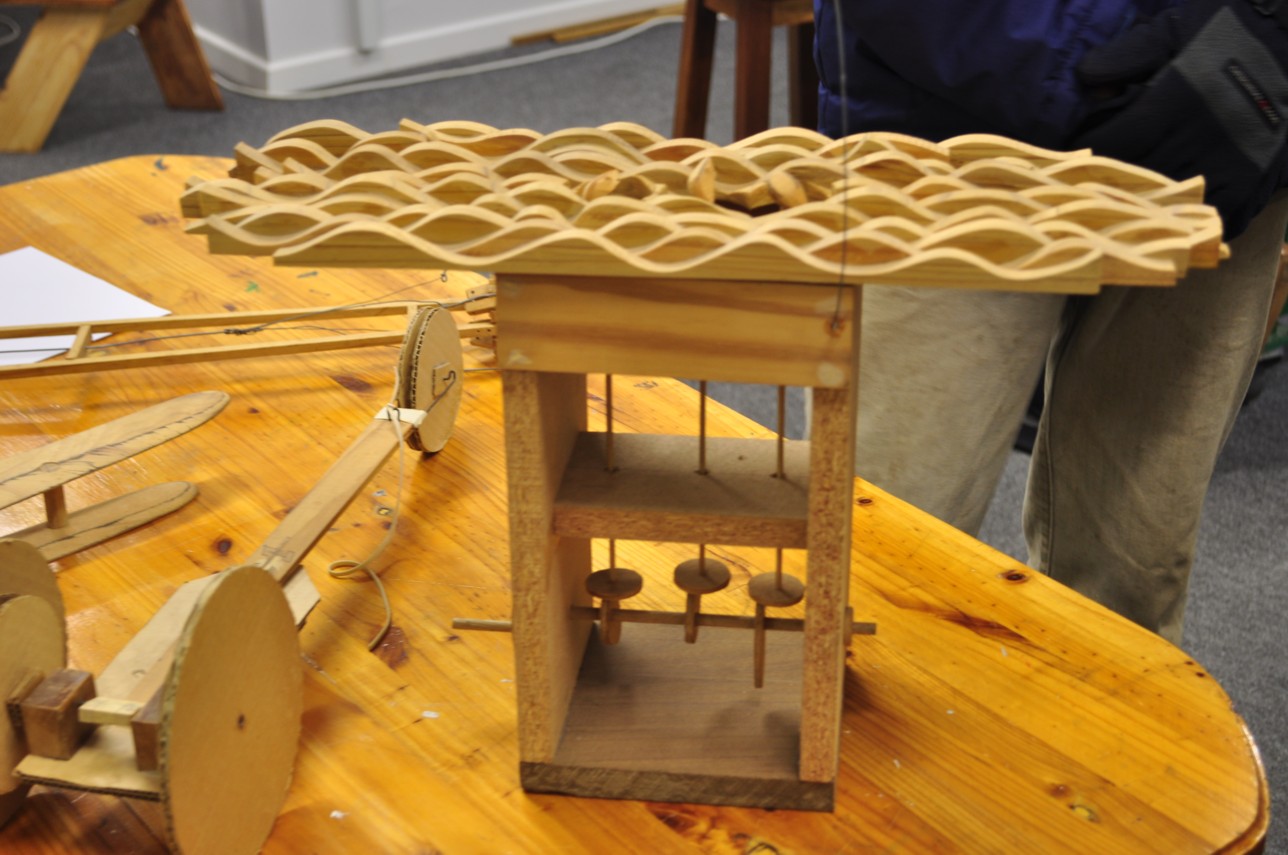

Wouter Holleman showed some carved Chinese screens.

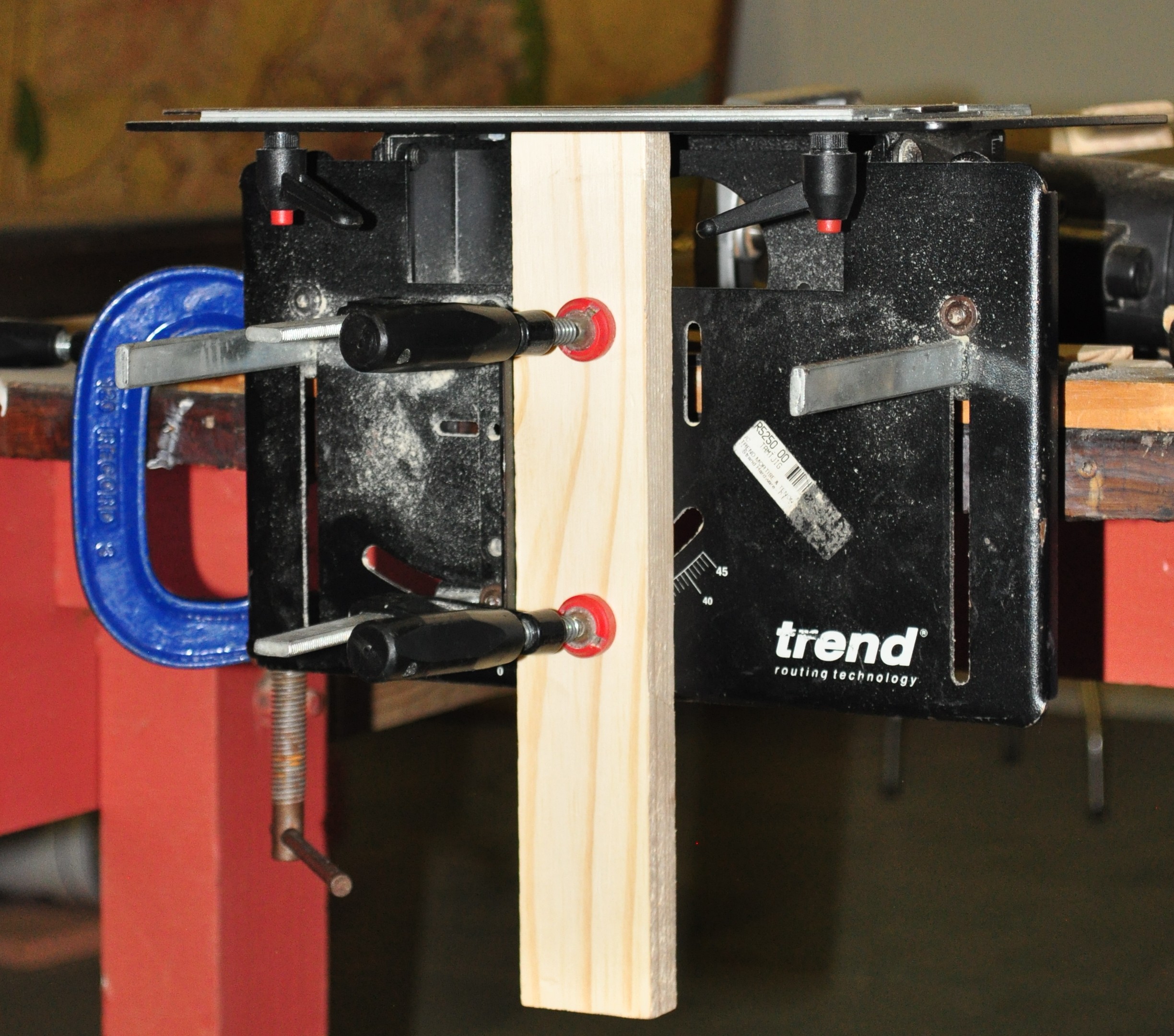

Chris Terry then demonstrated his drum sander attachment for a lathe, which is particularly valuable for thinning down pieces of wood too thin for a normal thicknesser.

The drum sander on the Jet lathe |

The adjustable ramp |

Chris Terry and the sander |

Another view |

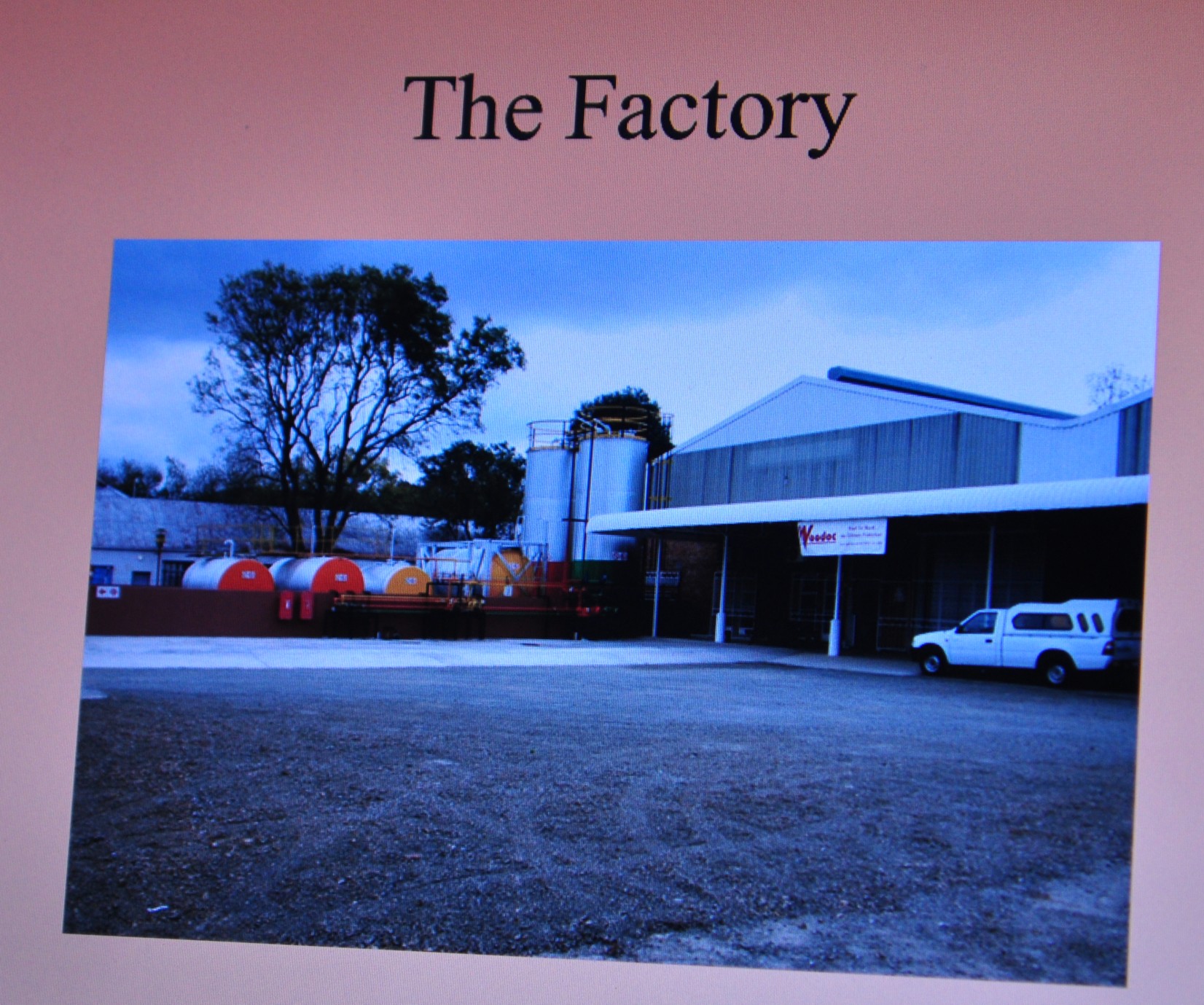

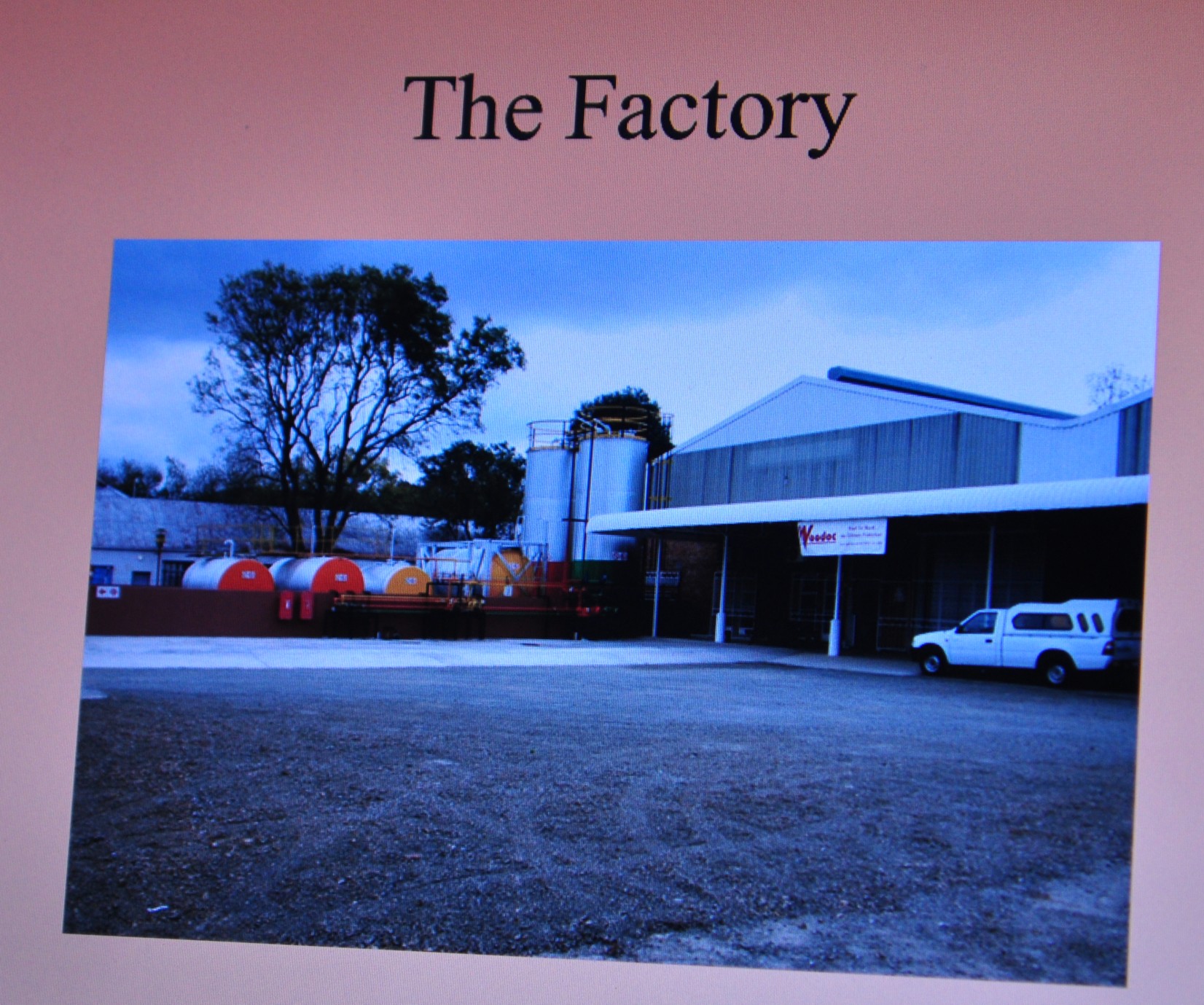

The OCTOBER meeting was a presentation by Mr Frikkie Greeff of WOODOC products and their correct application. This was held again at the Design and Technology Centre at St. Andrew's College. The photos below, by John Keulder give some idea of the presentation but more detail can be obtained by visiting their website.

Visit the Woodoc website.

" Mr WOODOC" - Frikkie Greeff |

The enthusiastic audience |

The WOODOC factory in Fort Beaufort |

Some of the huge range of products |

Deck protection |

Product display |

Coated samples |

Refreshments provided! |

The AGM AND END-OF-YEAR MEETING took place on Tuesday, NOVEMBER 12 at Rob Mossís farm.

The current Committee was re-elected for 2014 and is Billy de Klerk(Chairman), Chris Terry (Treasurer), Mike Brown (Secretary), Andrew Stevens, Rob Moss, Peter Breetzke, Patty Zipp, Koekoe Jonker and Wouter Holleman. Rob Moss stood down as Chairman as he is retiring to Bushman's River. He was thanked for his energetic leadership during the year.

Many toys, books, cash donations and items of clothing were collected for Hospice.

Collecting for Hospice and the Auction |

Some of the Committee |

Accompanying persons and Guests |

AGM audience |

Chris Terry and finances |

Rob Moss, retiring Chairman |

Rob Moss, auctioneer |

Sold to ???? |

Patty Zipp's lucky draw |

Pick a Prize |

Some of the Grahamstown Woodworkers manned a stall at the NGK Christmas Market, held this year for the first time at the PJ Olivier School hall. Some photos of the goods on display are given below.

BACK TO HOME

PAGE

Page last modified on 20 DECEMBER 2013