What type of woodworker are you?

Dust extraction a must in all workshops

Ample lighting

Ample plug points (plug points suspended from ceiling work very well – no tripping over wires

Most well laid-out workshops have ample work benches and work space

Most workshops should have at least two exits

Wheels desirable on most machines, especially if you have a small workshop

Combination tools are ok if you have a small workshop

Melamine top for glue-up bench

Try and protect clamps from glue spillage – discolouration of tools and wood projects

Noise factor a big consideration when designing or equipping workshops

Safety a major concern – goggles and hearing & dust masks

Be careful of cluttering workshop floor to prevent accidents etc…

Solar power or light ducts can aid for better lighting

Extension tables essential for a number of tools

Brakes on most wheeled tools – sample

BEST TOOLS TO START WITH:(DEPENDING ON WHAT YOUR INTERESTS ARE)

BANDSAW

ROUTER

TABLE SAW

THICKNESSER

SMALL TOOLS ARE A GIVEN (DRILLS, BISCUIT JOINTERS PALM SANDERS, BELT SANDERS ETC….)

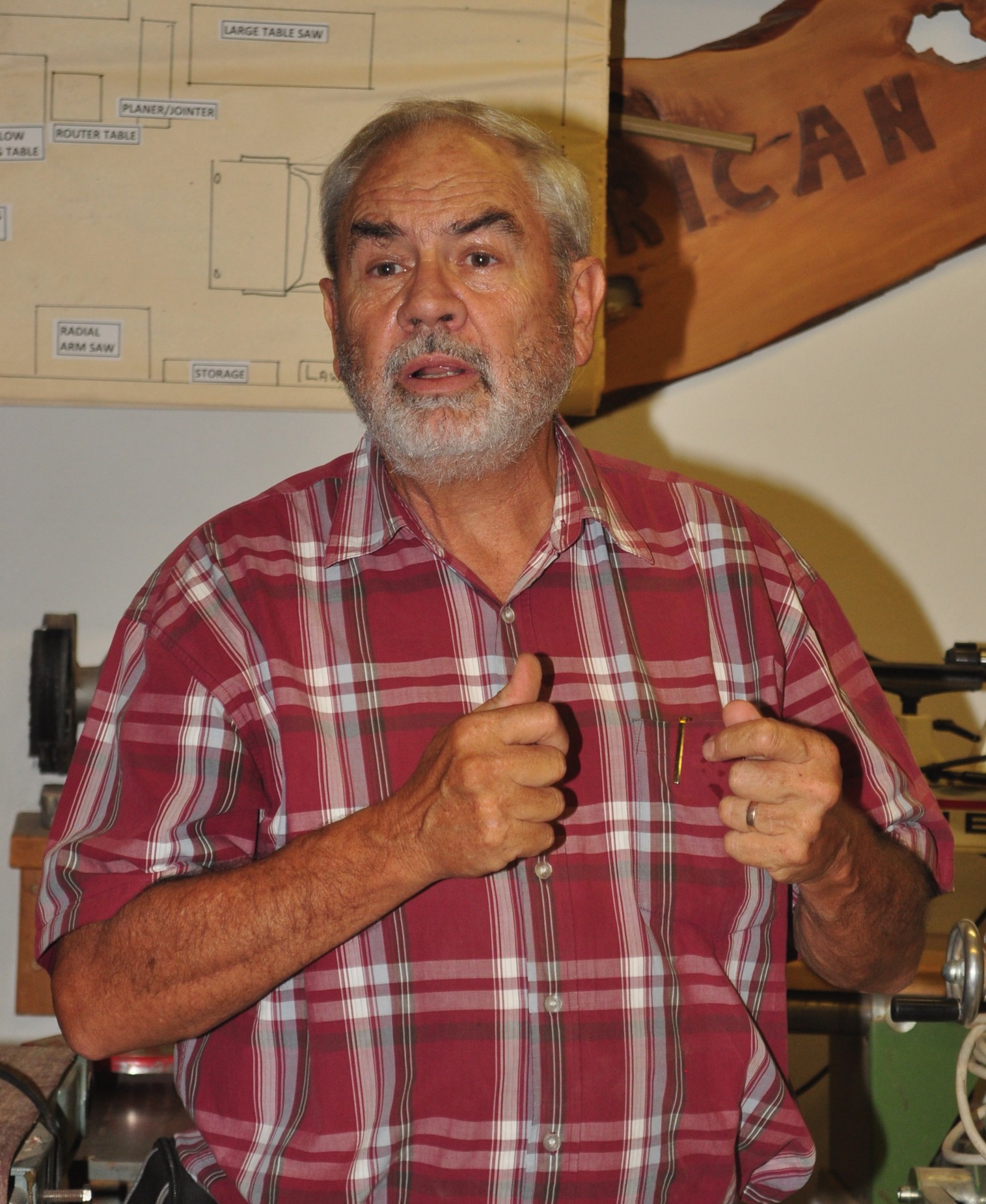

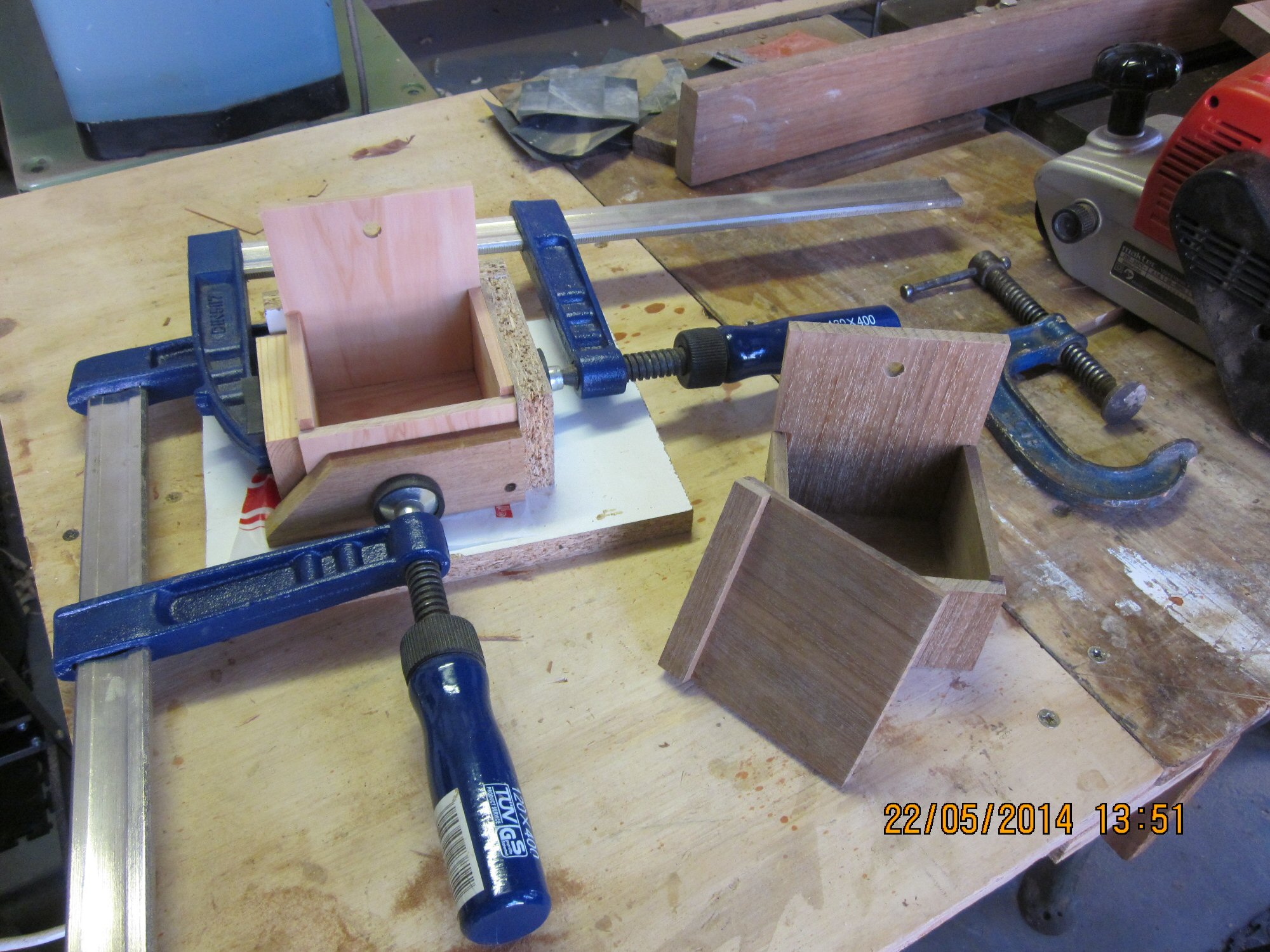

Andy also demonstrated how to make a chessboard and some photos are given below.

New Chairperson: Billy de Klerk |

A view of Andy's spotless workshop |

Another view |

Andy and the chessboard stages |

Cutting |

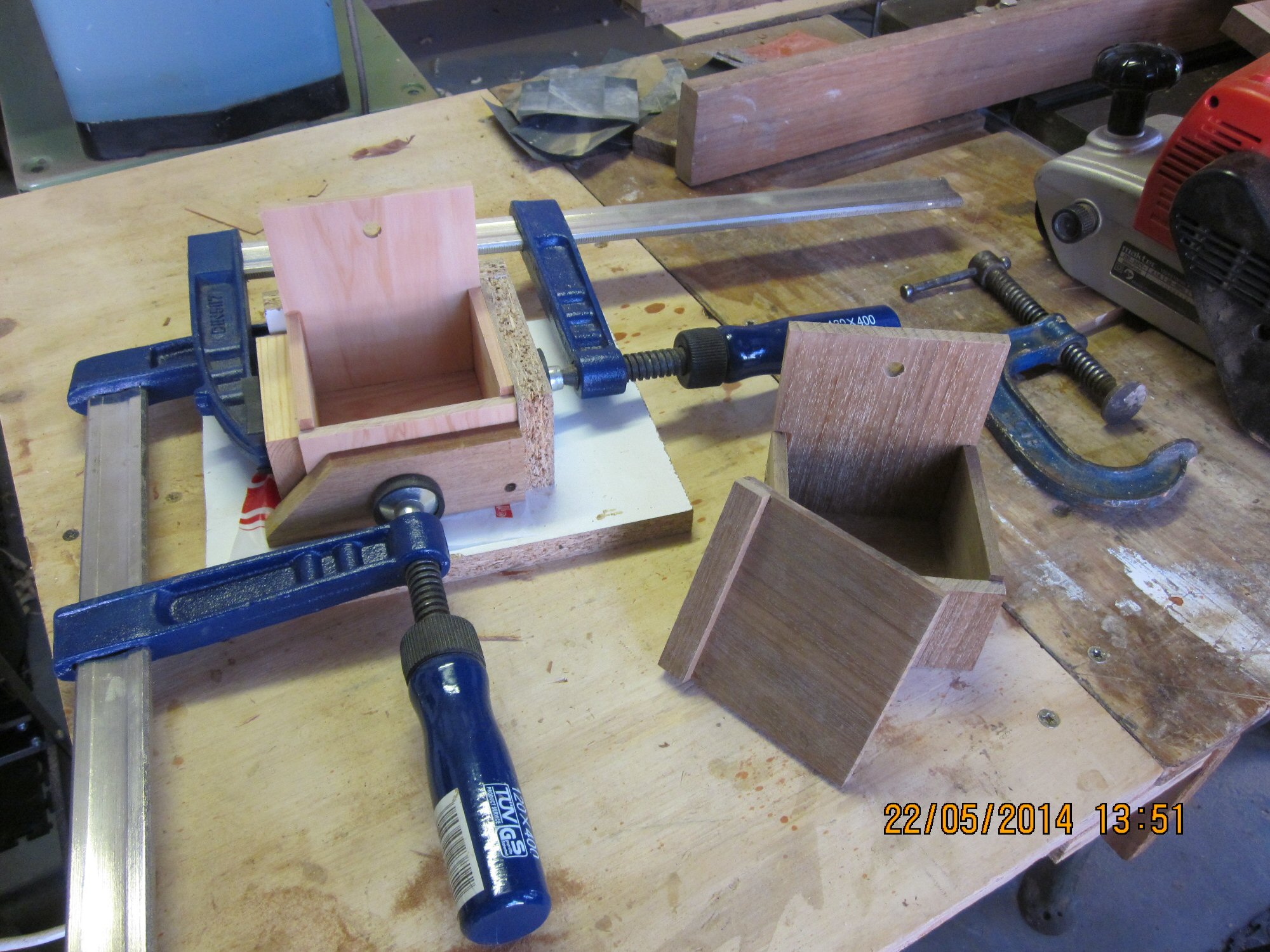

Gluing and clamping |

The chessboard |

The board made into a chess table |

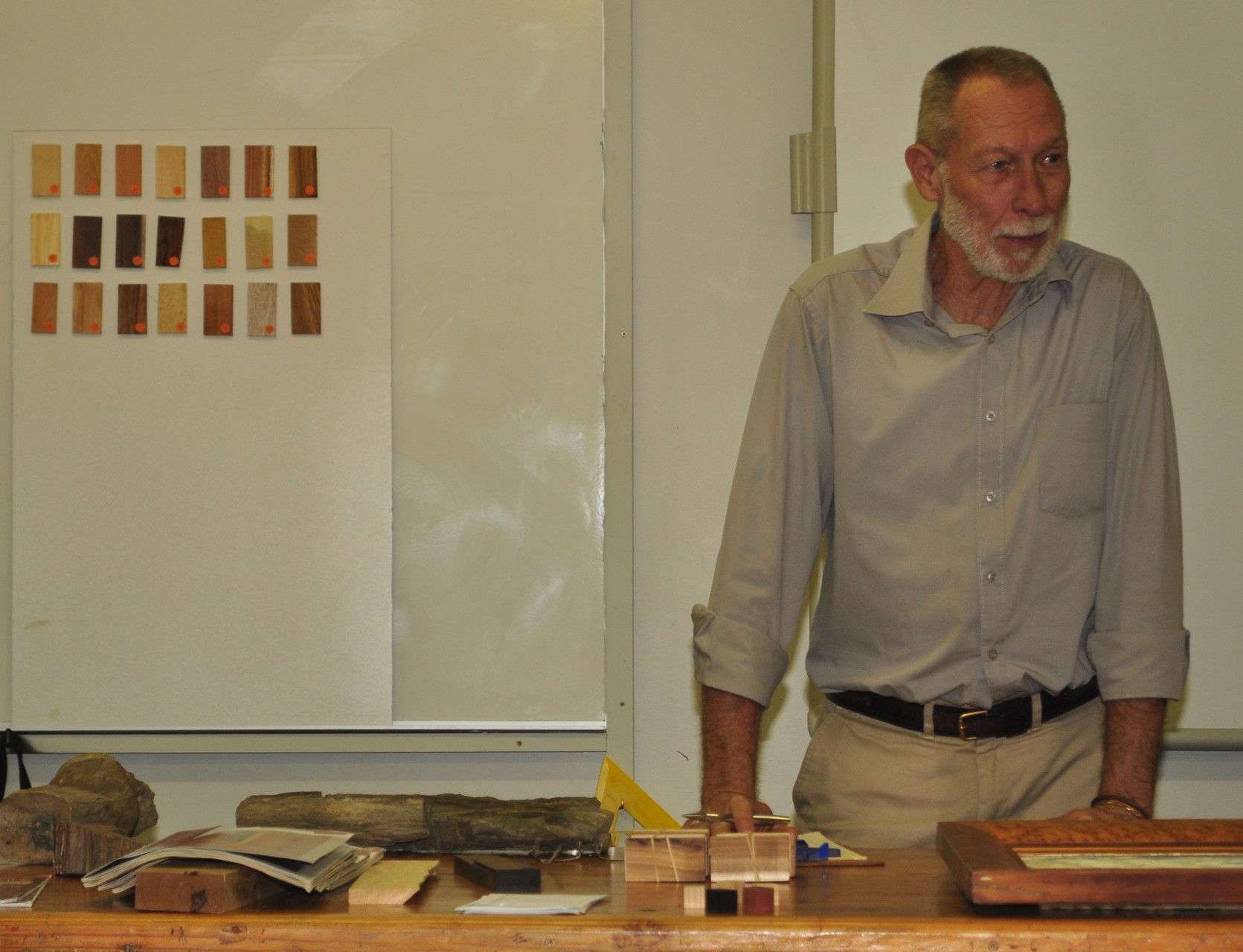

The MARCH meeting was held in our "home", the St Andrews Design & Technology Centre. The focus of the meeting was on "The Identification of Wood" with a presentation by Andrew Stevens. The PowerPoint presentation can be downloaded (see below).

After the presentation, Andrew identified some examples brought by members - a mahogany stool and a picture frame with bird'seye maple veneer. Andrew had also prepared a set of examples of woods to be identified by members.

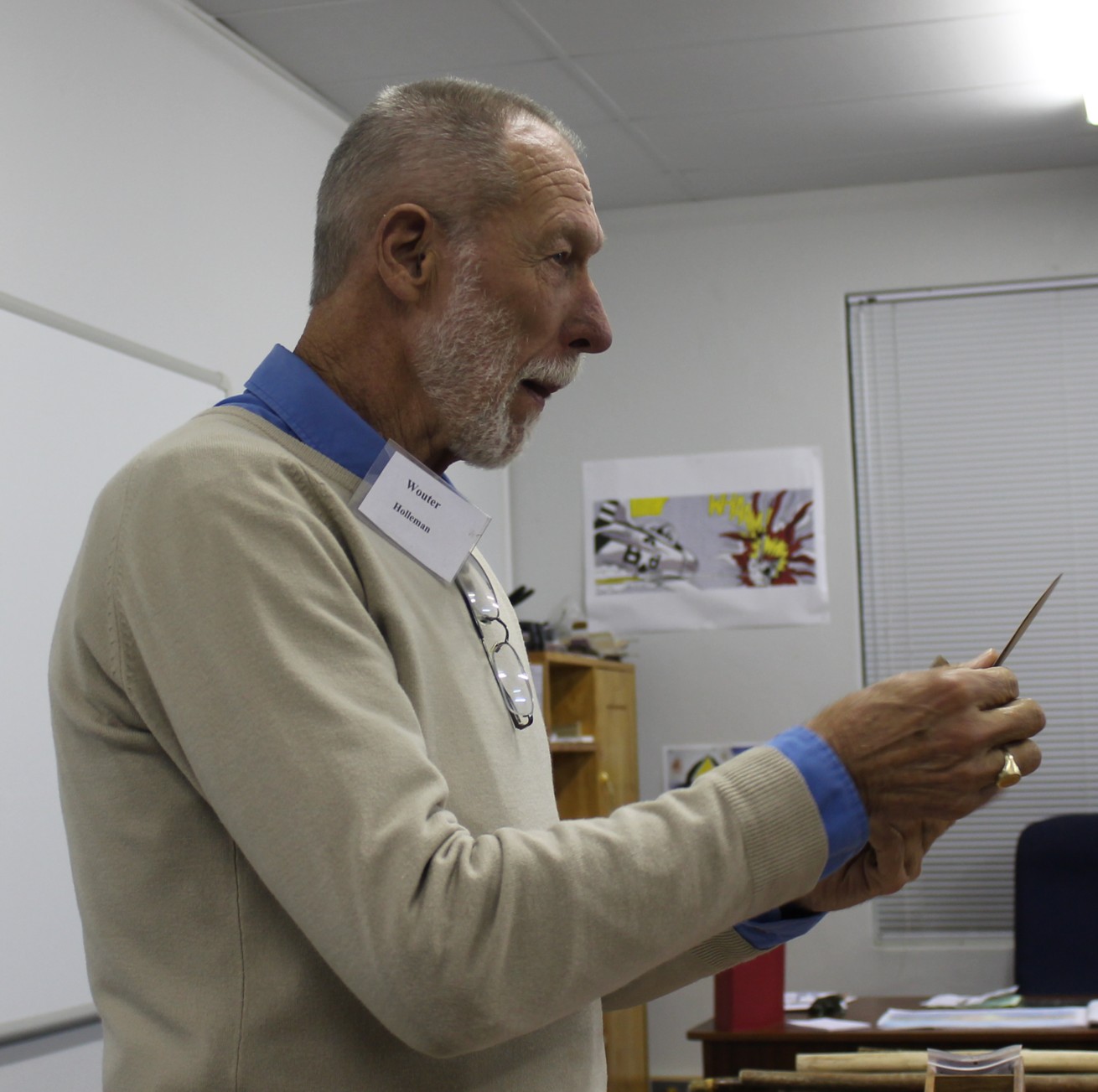

After this Wouter Holleman explained the silent auction of lots of wood from Ian Macdonald's workshop. Wouter and Billy de Klerk put a huge amount of work into this sale and members got some real bargains.

Download the presentation by Andrew Stevens on the Identification of Wood

Andrew Stevens |

Andrew Stevens and Billy de Klerk |

Wouter Holleman explains the auction |

Mike Palmer tackles the test |

Identifying examples |

A picture frame with bird'seye maple veneer |

The sale and auction in progress |

Another view |

On the 15th March the Grahamstown Woodworkers took part in the annual Hobbies Fair. Andrew Stevens demonstrated the turning of cylindrical boxes with lids and Andy Hatting demonstrated the secrets of making picture frames. Fuller versions of these demonstrations will be given at our regular meetings. Some of the Woodworkers' products were also on display - see the photos below.

The APRIL meeting was held in the St Andrews Design & Technology Centre. Andrew Stevens demonstrated the turning of lidded cylindrical boxes. An article from "Fine Woodworking" can be downloaded (see below).Photos below by John Keulder.

Download article

Andrew Stevens,the Jet lathe, chisel selection and completed boxes |

Blanks for box and lid |

Blank mounted on screw chuck |

Rounding the outside |

Beginning the hollowing |

Finished box |

Another view |

Working on the lid |

Finished lidded box |

Another view |

Another box |

Another view |

The MAY meeting was, as usual, held in the St Andrews Design & Technology Centre. With the Festival coming up in July, some of the woodworkers involved in our stall demonstrated the skills and techniques involved in making some of their popular products, which range from pens and peppermills to walking sticks. There was also some interesting discussion on the pricing of items.

Photos below by Andy Hatting.

Rob Moss started the evening by showing a solid oak tray. There was discussion of the need to allow movement of the wood panel making up the tray base and the avoidance of glue across the panel. He then spoke about the making of his very popular remote holders and the use of a drum sander to make thin panels.

Rob Moss and the tray |

The TV remote holder |

Wouter Holleman then spoke about his wooden butter knives, his salt boxes and his book reading stands.

Wouter holding up a butter knife |

A closer look at the knives |

Book stand |

Salt boxes in preparation |

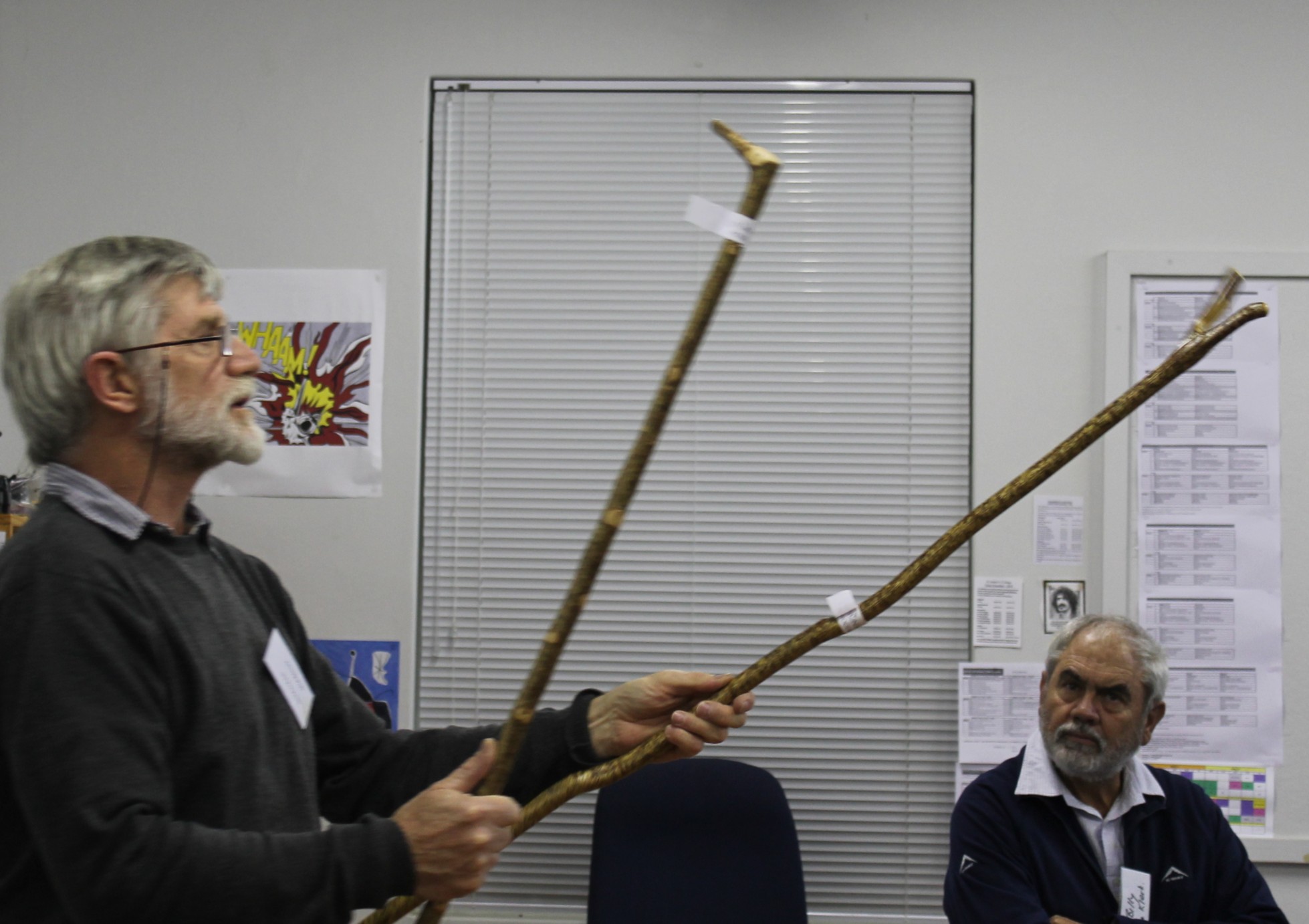

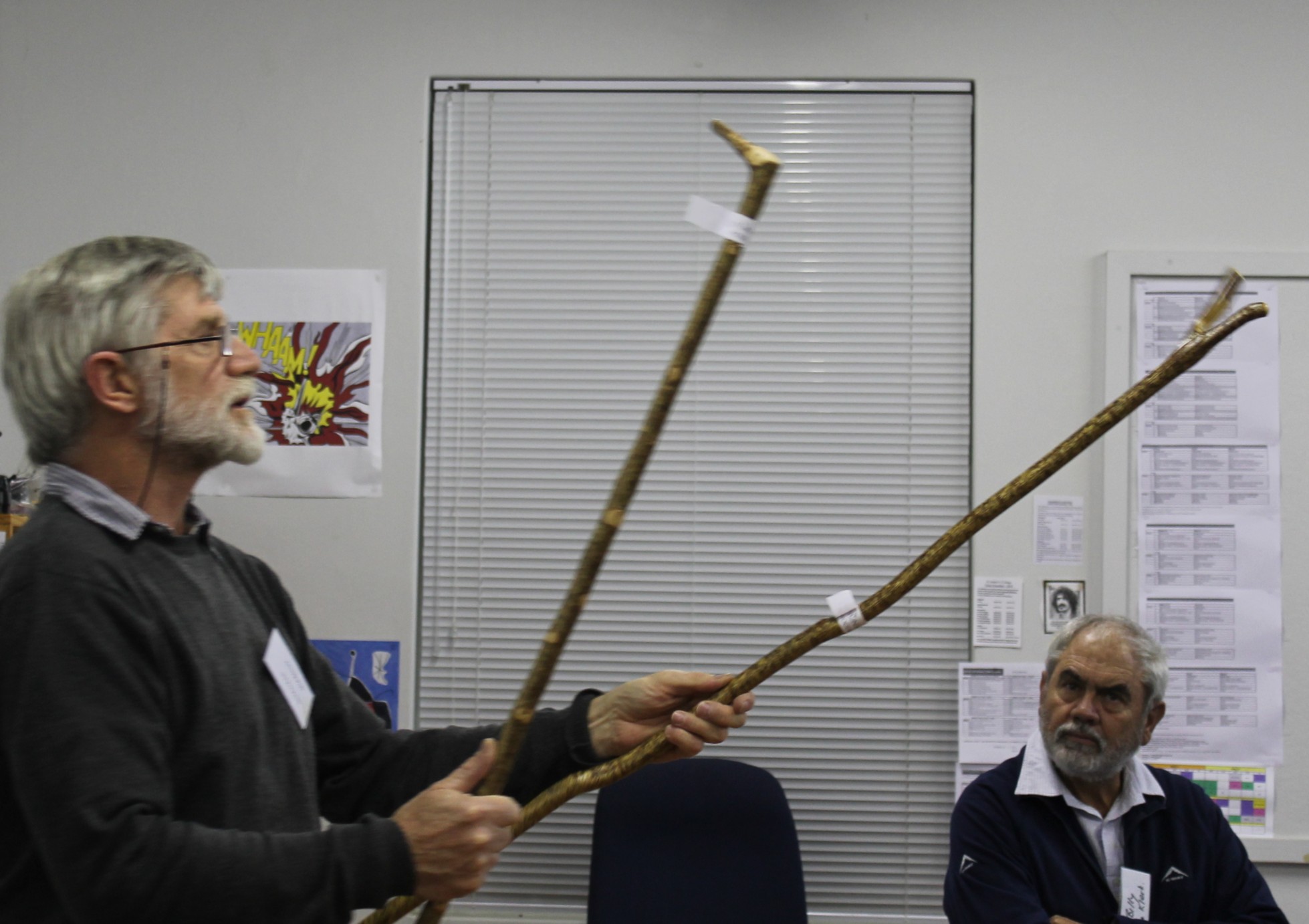

Andrew Stevens described the various techniques needed in making walking sticks and displayed a selection made from hazelnut wood.

Andrew Stevens and a walking stick |

Some more rustic examples |

Koos Jonker has built up an enviable reputation for his magnificent 1/12th scale dolls house furniture. He explained the problems of working on this miniature scale and also stressed the value of a drum sander for safely preparing the thin starting material.

Koos Jonker and his miniature furniture |

Another view |

Peter Breetzke is a specialist in the making of elegant pens and pencils. He showed some of the equipment needed and techniques used. He also spoke about sources for the pen parts.

Peter Breetzke and his pens and pencils |

Some of the equipment needed |

|

|

A display of the range |

The JUNE meeting focussed on framing techniques. [Photos below by John Keulder.]

Andy Hatting showed some of the ways of clamping picture frames, using a very efficient strap clamp and also a homemade diagonal clamp for large frames.

Mike Brown discussed some of the problems of making a circular mirror frame from four segments and the router jig required.

Andrew Stevens demonstrated a shooting board for using a plane to accurately trim mitre joints.

Andrew went on to demonstrate additional clamps for frames and the use of the PUSHMASTER framing kit, available from Strand Hardware, for pinning corners and holding the picture or mirror in place.

On Saturday 9th August a party of Grahamstown Woodworkers visited the Woodoc factory in Fort Beaufort. They were royally hosted by Mr Freddie Greeff and after lunch at the Country Club were given a guided tour of Fort Beaufort by Mr Gert van der Westhuizen.

Mr Frikkie Greeff from Woodoc |

The visitors |

Inside the factory |

With the products |

Visit the Woodoc website.

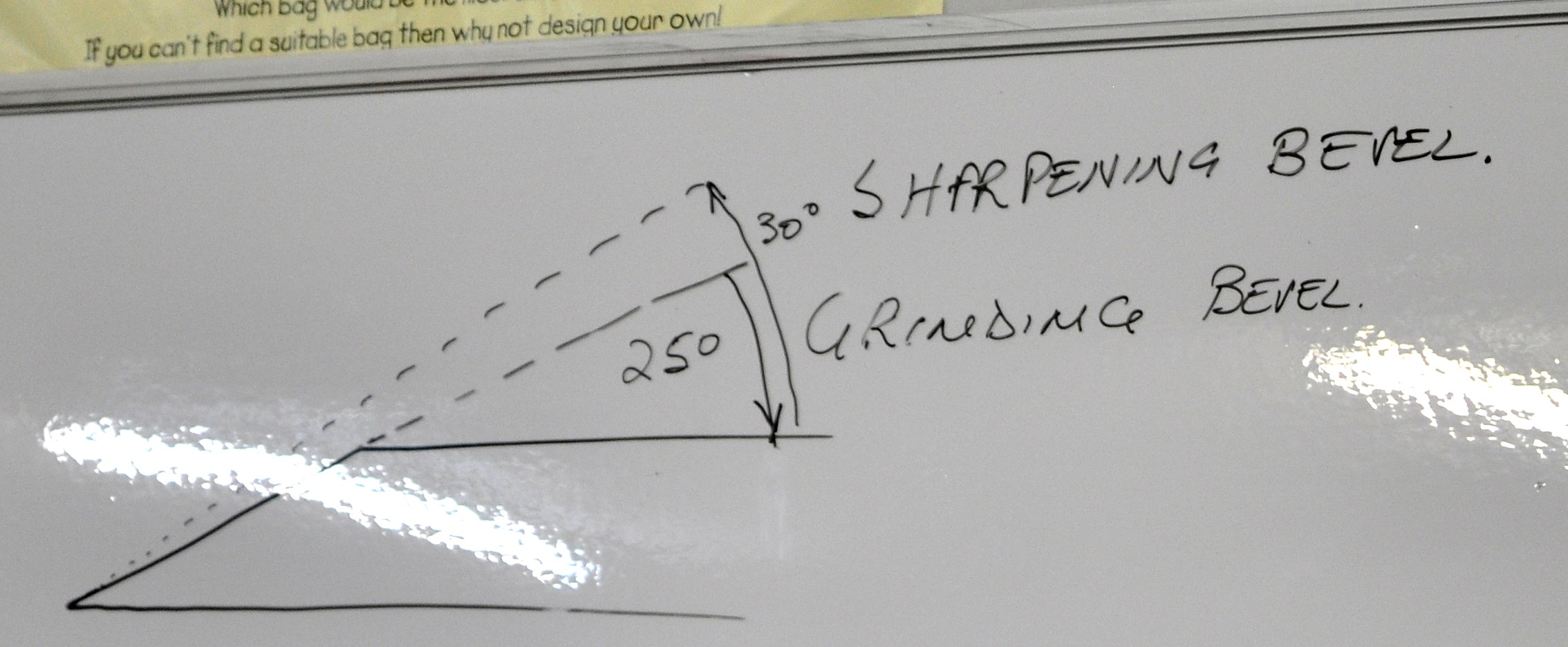

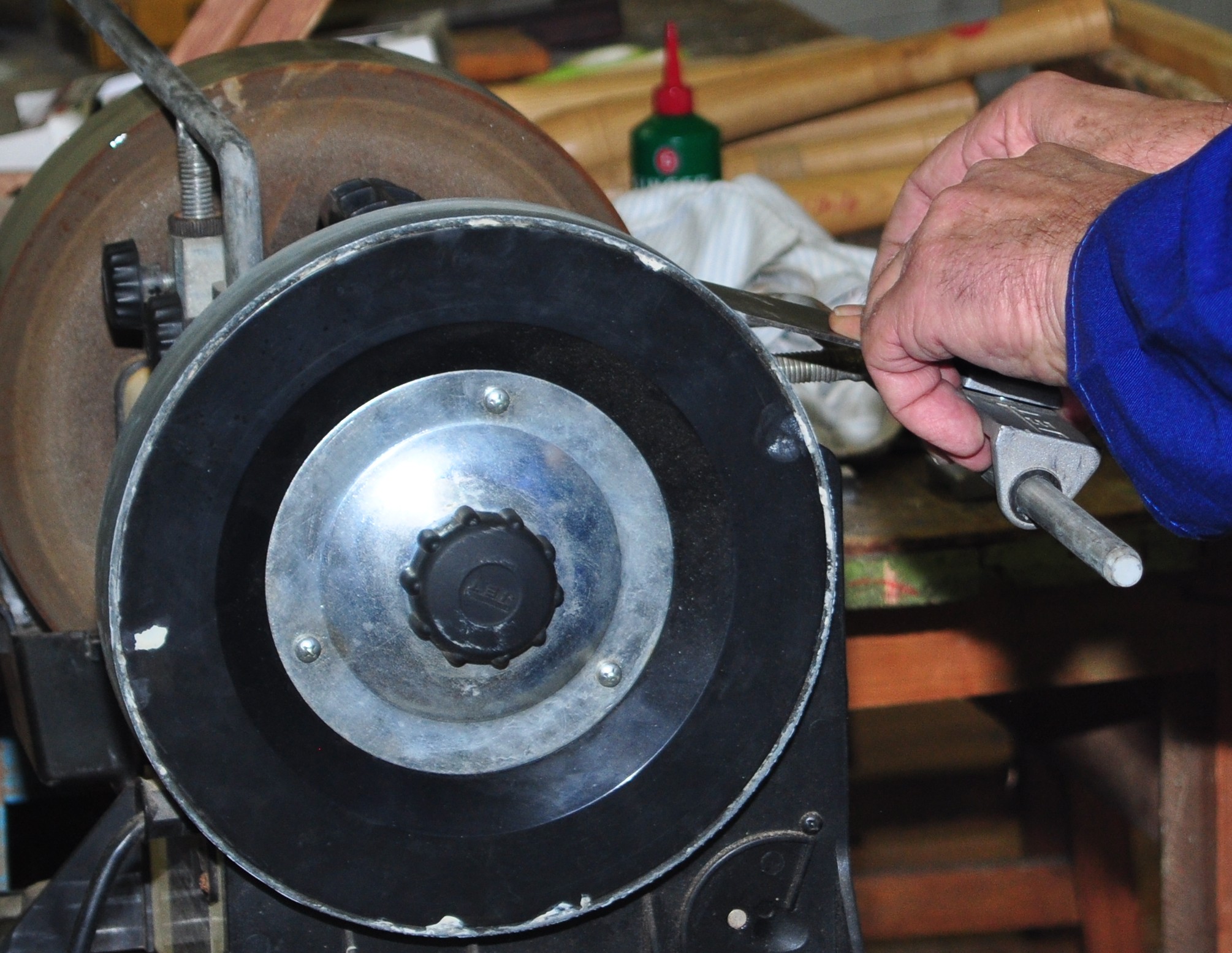

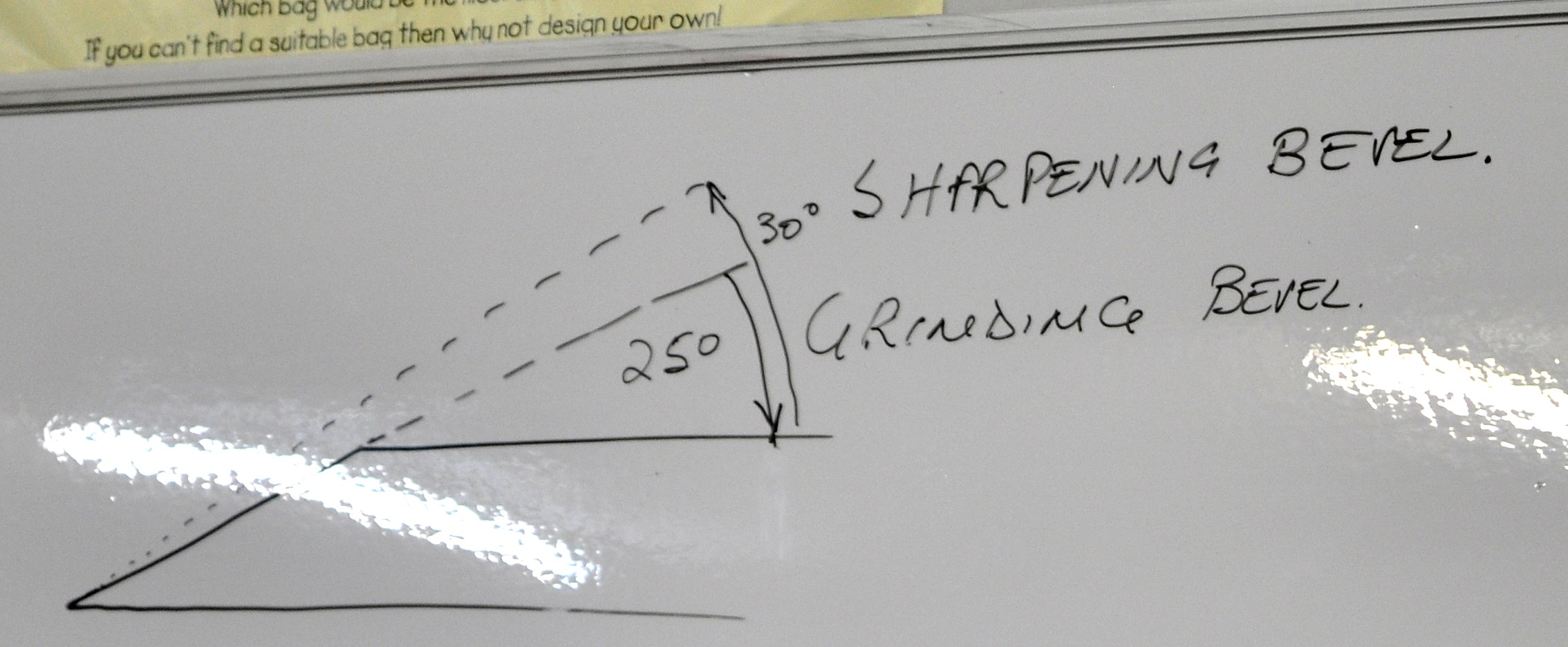

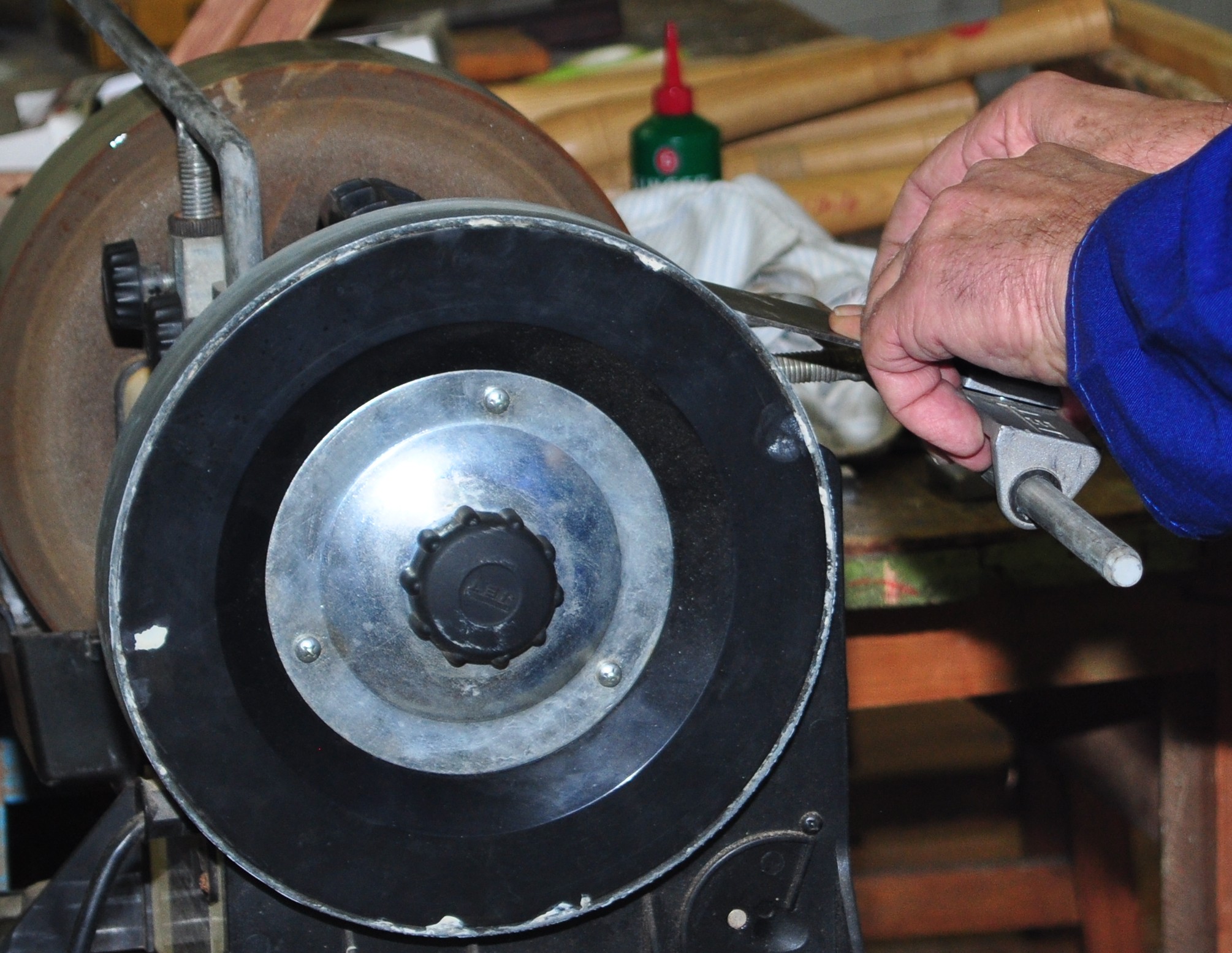

The regular AUGUST meeting featured a visit from Strand Hardware of Port Elizabeth and a demonstration by Andre Esterhuyze of techniques and equipment for sharpening edge tools. [Photos below by John Keulder.]

Andre Esterhuyze and Gerard Wong from Strand Hardware |

Close up of the Jet waterstone sharpener, a copy of the well-known Tormek system |

The jig for plane blades and chisels |

The grinding and sharpening angles on a plane blade |

The angle-gauge accessory |

Using the wetstone with the jig |

Applying "Autosol" polishing paste to the stropping wheel |

Stropping on the wheel |

Using an oilstone, or even sandpaper on plate glass, as an alternative method of sharpening |

Flattening the back of the bevel |

How the plane blade and the back-iron should be adjusted. Note the gap in the angle of contact |

How the plane blade should protrude from the sole |

Sharpening a bowl gouge using a jig |

Another view as the gouge is rotated |

Sharpening a large roughing gouge |

Leather wheel for small gouges and carving chisels |

Some of the "temptations" on display and for sale |

Visit the website of Strand Hardware, PE

BACK TO HOME

PAGE

Page last modified on 20 AUGUST 2014